Using ratchet straps correctly and safely is essential for securing cargo. At HOW.EDU.VN, we offer expert guidance on utilizing these versatile tie-down straps and similar load securement methods, addressing common questions like threading and releasing the straps while ensuring your load is safely secured. With our advice, you will master safe cargo securement, load security, and proper tie-down techniques.

1. What Are Ratchet Straps and How Do They Work?

Ratchet straps are tie-down devices used to secure cargo during transportation. They consist of a webbing strap, a ratchet mechanism, and end fittings (such as hooks or D-rings). The ratchet mechanism allows you to tighten the strap, holding the cargo firmly in place.

Ratchet straps work by providing a strong and adjustable tensioning force. According to the Commercial Vehicle Safety Alliance (CVSA), proper use of ratchet straps is critical for preventing cargo shifting and ensuring road safety.

Here’s how they function:

- Attachment: The end fittings are attached to anchor points on the cargo and the vehicle.

- Threading: The strap is threaded through the ratchet mechanism.

- Tightening: The ratchet is used to tighten the strap, creating tension.

- Locking: Once tightened, the ratchet locks to maintain tension.

The primary purpose of ratchet straps is to secure loads and prevent movement during transit. This reduces the risk of accidents and damage to the cargo. Different types of ratchet straps and tie-downs are available, including those made from polyester webbing suitable for various trailers and truck beds. HOW.EDU.VN offers comprehensive guidance on selecting the right ratchet strap for your specific needs, ensuring optimal load security.

2. What are the Key Components of a Ratchet Strap System?

Understanding the components of a ratchet strap system is essential for its safe and effective use. A typical ratchet strap system includes the following key parts:

- Webbing Strap: Made from durable materials like polyester or nylon, the webbing provides the main load-bearing component of the strap. Polyester webbing is preferred due to its low stretch and resistance to abrasion and UV rays, according to the Web Sling & Tie Down Association (WSTDA).

- Ratchet Mechanism: This is the heart of the system, providing the tensioning force needed to secure the load. The ratchet mechanism includes a handle, a pawl, and a spool.

- End Fittings: These connect the strap to the anchor points and come in various forms, such as:

- Hooks: S-hooks, J-hooks, and flat hooks.

- D-rings: Used for creating secure attachment points.

- Snap Hooks: Provide quick and easy attachment.

- Handle: The handle is used to operate the ratchet mechanism.

- Release Lever: This lever disengages the ratchet, allowing the strap to be loosened.

- Frame: Provides structural support for the ratchet mechanism.

Different types of webbing materials offer varying degrees of strength and durability, affecting the overall performance of the strap. For instance, high-tenacity polyester webbing is commonly used for heavy-duty applications due to its superior strength and resistance to stretching. According to a study by the Department of Transportation (DOT), using the correct components and materials significantly reduces the risk of cargo damage and accidents.

3. How Do You Choose the Right Ratchet Strap for Your Load?

Selecting the appropriate ratchet strap involves considering several factors to ensure your load is safely secured. Here are key considerations:

- Working Load Limit (WLL): The WLL is the maximum weight the strap is designed to hold safely. Always choose a strap with a WLL that meets or exceeds the weight of your cargo.

- Breaking Strength: This is the force at which the strap will fail. The WLL is typically one-third of the breaking strength, providing a safety margin.

- Strap Length and Width: The length should be sufficient to wrap around your cargo and reach the anchor points. The width affects the strap’s strength and durability. Wider straps generally have higher WLLs.

- End Fittings: Select end fittings that are appropriate for your anchor points. Hooks, D-rings, and snap hooks each have their advantages, depending on the application.

- Material: Polyester webbing is a common choice due to its strength, low stretch, and resistance to weather and abrasion.

- Type of Cargo: Consider the nature of your cargo. Sharp edges may require additional protection to prevent the strap from being cut or damaged.

- Regulations: Ensure the straps meet the standards set by organizations like the Commercial Vehicle Safety Alliance (CVSA) and the Department of Transportation (DOT).

Different types of cargo require specific types of ratchet straps. For example, securing heavy machinery will require heavy-duty straps with high WLLs, while securing lighter items may allow for smaller, lighter straps. According to safety guidelines from the Web Sling & Tie Down Association (WSTDA), selecting the right strap involves assessing the load’s weight, size, and shape, as well as the environmental conditions during transport.

Ratchet strap securing a load on a truck bed

Ratchet strap securing a load on a truck bed

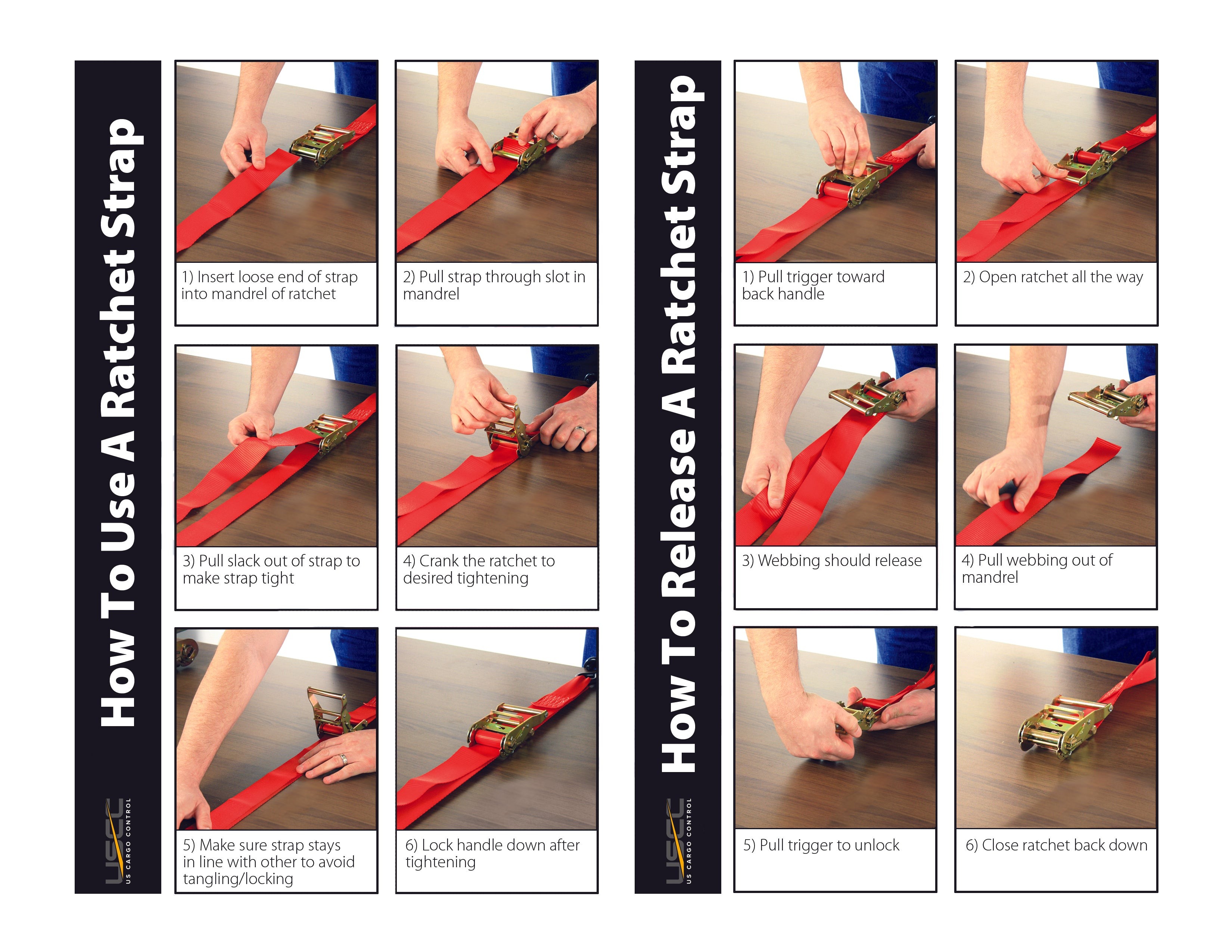

4. What are the Step-by-Step Instructions on How to Use a Ratchet Strap?

Using a ratchet strap involves several steps to ensure proper and safe cargo securement. Here is a detailed guide:

- Inspect the Straps:

- Check the webbing for any signs of wear, cuts, or damage.

- Ensure the ratchet mechanism is in good working order.

- Verify the end fittings are not bent or broken.

- Position the Cargo:

- Place the cargo in the desired location on the truck bed or trailer.

- Ensure the cargo is stable and evenly distributed.

- Attach the End Fittings:

- Connect the end fittings to secure anchor points on the vehicle.

- Make sure the attachment is secure and the hooks are fully engaged.

- Thread the Strap:

- Insert the strap through the slot in the ratchet spool.

- Pull the strap through, leaving enough slack to wrap around the cargo.

- Wrap the Strap Around the Cargo:

- Wrap the strap around the cargo, ensuring it is positioned correctly.

- Avoid twisting or kinking the strap.

- Tighten the Strap:

- Begin ratcheting the strap by moving the handle back and forth.

- Continue until the strap is snug and the cargo is secure.

- Avoid overtightening, which can damage the cargo or the strap.

- Lock the Ratchet:

- Ensure the ratchet is locked in place to maintain tension.

- Double-check the strap to ensure it is properly secured.

- Secure Excess Webbing:

- Tie off any excess webbing to prevent it from flapping in the wind.

- Use rubber bands or tape to keep the webbing secure.

- Inspect Regularly:

- During transit, periodically check the straps to ensure they remain tight and secure.

- Retighten if necessary.

- Release the Strap:

- To release, disengage the ratchet mechanism by pulling the release lever.

- Carefully unwind the strap, ensuring the cargo does not shift unexpectedly.

Following these steps will help ensure that your cargo is safely secured. According to safety recommendations from the National Highway Traffic Safety Administration (NHTSA), proper use of ratchet straps is crucial for preventing accidents and ensuring the safety of all road users. At HOW.EDU.VN, our experts can provide detailed demonstrations and personalized advice to help you master these techniques.

5. What Are Common Mistakes to Avoid When Using Ratchet Straps?

Avoiding common mistakes when using ratchet straps is crucial for ensuring cargo safety and preventing accidents. Here are some frequent errors to watch out for:

- Exceeding the Working Load Limit (WLL): Overloading straps can cause them to fail, leading to cargo damage or accidents.

- Using Damaged Straps: Straps with cuts, abrasions, or damaged hardware should never be used.

- Improper Attachment: Failing to securely attach the end fittings to anchor points can result in the straps coming loose.

- Overtightening: Overtightening can damage the cargo or the straps themselves.

- Using the Wrong Type of Strap: Different types of cargo require specific straps. Using an inadequate strap can compromise safety.

- Ignoring Regulations: Failing to comply with safety standards set by organizations like the CVSA and DOT can lead to fines and penalties.

- Neglecting Regular Inspections: Straps should be checked regularly during transit to ensure they remain tight and secure.

- Incorrect Threading: Improperly threading the strap through the ratchet mechanism can reduce its effectiveness.

- Failing to Secure Excess Webbing: Loose webbing can flap in the wind, creating a hazard and potentially loosening the strap.

- Using Straps for Lifting: Ratchet straps are designed for tie-down purposes only and should never be used for lifting.

Correcting these common mistakes involves proper training, regular inspections, and adherence to safety guidelines. According to a study by the Federal Motor Carrier Safety Administration (FMCSA), most cargo securement failures are due to human error, emphasizing the importance of proper training and technique. At HOW.EDU.VN, our experts offer comprehensive training and support to help you avoid these pitfalls and ensure the safe transport of your cargo.

6. What are the Best Practices for Maintaining Ratchet Straps?

Proper maintenance of ratchet straps ensures their longevity and reliability. Here are some best practices to follow:

- Regular Inspections:

- Inspect straps before each use for signs of wear, cuts, or damage.

- Check the ratchet mechanism for smooth operation and proper locking.

- Examine end fittings for bends, cracks, or corrosion.

- Cleaning:

- Clean straps regularly with mild soap and water to remove dirt and grime.

- Avoid using harsh chemicals that can damage the webbing.

- Storage:

- Store straps in a dry, cool place away from direct sunlight.

- Avoid storing straps in areas where they can be exposed to chemicals or extreme temperatures.

- Protection:

- Use edge protectors when securing cargo with sharp edges to prevent abrasion.

- Protect straps from UV exposure, which can weaken the webbing over time.

- Proper Use:

- Follow the manufacturer’s instructions for proper use and care.

- Avoid overloading straps beyond their working load limit.

- Replacement:

- Replace straps immediately if they show signs of damage or wear.

- Do not attempt to repair damaged straps.

- Lubrication:

- Periodically lubricate the ratchet mechanism to ensure smooth operation.

- Use a silicone-based lubricant to prevent corrosion.

- Documentation:

- Keep a record of strap inspections and maintenance activities.

- Track the age and usage of each strap to determine when it should be replaced.

Adhering to these best practices will help prolong the life of your ratchet straps and ensure they perform safely and reliably. According to the Web Sling & Tie Down Association (WSTDA), regular maintenance and inspections are critical for maintaining the integrity of tie-down equipment. At HOW.EDU.VN, our experts can provide detailed guidance on implementing these practices and ensuring the optimal performance of your ratchet straps.

7. How Do Weather Conditions Affect the Use of Ratchet Straps?

Weather conditions can significantly impact the performance and safety of ratchet straps. Here’s how different conditions can affect their use:

- Rain and Humidity:

- Wet conditions can reduce the friction between the strap and the cargo, making it easier for the load to shift.

- Moisture can also promote corrosion of metal components, such as ratchet mechanisms and end fittings.

- Polyester webbing is less susceptible to water damage compared to nylon, but it can still absorb some moisture, affecting its strength.

- Extreme Temperatures:

- High temperatures can weaken the webbing material over time, reducing its breaking strength.

- Cold temperatures can make the webbing stiff and more prone to cracking.

- Extreme temperature fluctuations can also affect the ratchet mechanism, causing it to bind or malfunction.

- Snow and Ice:

- Snow and ice can create slippery surfaces, making it more difficult to secure cargo.

- Ice buildup on the straps can reduce their flexibility and make them harder to tighten.

- The added weight of snow and ice on the cargo can increase the load on the straps.

- Sunlight (UV Exposure):

- Prolonged exposure to sunlight can degrade the webbing material, reducing its strength and elasticity.

- UV radiation can break down the fibers in the webbing, making it more susceptible to wear and tear.

- Wind:

- High winds can create additional forces on the cargo, increasing the stress on the straps.

- Wind can also cause the straps to vibrate, leading to abrasion and wear.

To mitigate these effects, it’s important to:

- Use Weather-Resistant Straps: Opt for straps made from materials like polyester, which are more resistant to water, UV radiation, and temperature extremes.

- Protect the Straps: Use tarps or covers to shield the cargo and straps from the elements.

- Increase Tension: In wet or windy conditions, increase the tension on the straps to compensate for reduced friction and added forces.

- Regularly Inspect: Check the straps more frequently during inclement weather to ensure they remain tight and secure.

- Adjust Techniques: Adapt your tie-down techniques to account for the specific weather conditions.

Understanding how weather conditions affect ratchet straps and taking appropriate precautions is essential for maintaining cargo safety. According to research from the National Weather Service, extreme weather events can significantly increase the risk of transportation accidents. At HOW.EDU.VN, our experts can provide tailored advice on adapting your cargo securement techniques to different weather conditions.

8. What are the Legal and Safety Regulations Regarding Ratchet Straps?

Compliance with legal and safety regulations is crucial when using ratchet straps to ensure cargo is transported safely and legally. Key regulations and guidelines include:

- Department of Transportation (DOT) Regulations:

- The DOT sets standards for cargo securement in the United States.

- These regulations specify requirements for the number and type of tie-downs needed based on the cargo’s weight and dimensions.

- DOT regulations also address the proper use and maintenance of tie-down equipment.

- Commercial Vehicle Safety Alliance (CVSA) Guidelines:

- The CVSA provides inspection procedures and guidelines for commercial vehicle safety.

- These guidelines include criteria for assessing the condition and proper use of ratchet straps.

- CVSA inspections can result in fines or out-of-service orders for non-compliance.

- Web Sling & Tie Down Association (WSTDA) Standards:

- The WSTDA develops technical standards for the design, manufacture, and use of tie-down equipment.

- These standards provide guidance on selecting appropriate straps, determining working load limits, and conducting inspections.

- North American Cargo Securement Standard (NACSS):

- NACSS is a set of harmonized cargo securement standards adopted by the United States, Canada, and Mexico.

- These standards cover a wide range of cargo types and tie-down methods, including ratchet straps.

- State and Local Regulations:

- Many states and local jurisdictions have their own regulations regarding cargo securement.

- These regulations may supplement or exceed federal requirements.

- Manufacturer’s Instructions:

- Always follow the manufacturer’s instructions for the proper use and maintenance of ratchet straps.

- These instructions typically include information on working load limits, inspection procedures, and storage guidelines.

- Training and Certification:

- Proper training is essential for ensuring that personnel understand and comply with cargo securement regulations.

- Some organizations offer certification programs for cargo securement specialists.

Adhering to these legal and safety regulations helps prevent accidents, protect cargo, and avoid fines and penalties. According to the Federal Motor Carrier Safety Administration (FMCSA), compliance with cargo securement regulations is a key factor in reducing truck-related accidents. At HOW.EDU.VN, our experts stay up-to-date with the latest regulations and can provide comprehensive guidance on ensuring compliance.

9. How Can You Secure Different Types of Cargo Using Ratchet Straps?

Securing different types of cargo requires specific techniques and considerations to ensure safe and effective transport. Here are some examples:

- Lumber and Construction Materials:

- Use multiple straps to secure bundles of lumber, ensuring they are evenly distributed.

- Place straps over the top of the load and around the sides, securing them to anchor points on the trailer.

- Use edge protectors to prevent the straps from cutting into the lumber.

- Vehicles (Cars, ATVs, Motorcycles):

- Use specialized tie-down straps designed for vehicle transport.

- Attach the straps to the vehicle’s frame or designated tie-down points.

- Ensure the straps are tightened evenly to prevent the vehicle from shifting.

- Use wheel straps or axle straps for added security.

- Heavy Machinery:

- Use heavy-duty ratchet straps with high working load limits.

- Attach the straps to secure anchor points on the machinery and the trailer.

- Use chains or additional tie-downs for extra security.

- Consider using direct tie-down methods to minimize movement.

- Palletized Goods:

- Use straps to secure the pallet to the trailer, preventing it from sliding.

- Wrap the straps around the pallet and through the pallet openings.

- Use corner protectors to prevent the straps from damaging the pallet or the goods.

- Cylindrical Objects (Pipes, Logs):

- Use V-shaped tie-down configurations to prevent the objects from rolling.

- Place straps over the top of the objects and secure them to anchor points on either side.

- Use chocks or cradles to provide additional support.

- Fragile Items:

- Use padding or cushioning to protect fragile items from damage.

- Avoid overtightening the straps, which can crush or break the items.

- Use wide straps to distribute the pressure evenly.

- Odd-Shaped Cargo:

- Assess the cargo’s center of gravity and secure it in a way that prevents tipping or shifting.

- Use a combination of straps and other tie-down devices to provide comprehensive securement.

- Consider using custom tie-down solutions for particularly challenging loads.

Tailoring your tie-down techniques to the specific characteristics of the cargo is essential for ensuring safe and secure transport. According to industry best practices, a thorough assessment of the cargo’s weight, dimensions, and stability is crucial for selecting the appropriate tie-down methods. At HOW.EDU.VN, our experts can provide customized guidance on securing a wide range of cargo types.

10. What Innovations are There in Ratchet Strap Technology and Materials?

Advancements in ratchet strap technology and materials have led to improvements in safety, durability, and ease of use. Here are some notable innovations:

- High-Performance Webbing Materials:

- Manufacturers are using advanced synthetic fibers, such as high-tenacity polyester and ultra-high molecular weight polyethylene (UHMWPE), to create webbing with increased strength and durability.

- These materials offer improved resistance to abrasion, UV radiation, and chemical exposure.

- Ergonomic Ratchet Mechanisms:

- New ratchet designs incorporate ergonomic handles and improved gearing ratios, making it easier to tighten straps with less effort.

- Quick-release mechanisms allow for faster and more controlled strap release.

- Smart Straps with Integrated Sensors:

- Some ratchet straps are equipped with sensors that monitor tension levels and provide real-time feedback to the user.

- These sensors can help prevent overtightening and ensure that the load remains secure during transport.

- Data from the sensors can be transmitted wirelessly to a mobile device or central monitoring system.

- Self-Tensioning Straps:

- Self-tensioning straps automatically adjust the tension to compensate for changes in load conditions.

- These straps use a spring-loaded mechanism to maintain constant tension, preventing the load from shifting.

- Anti-Abrasive Coatings:

- Webbing is being treated with specialized coatings that reduce friction and protect against abrasion.

- These coatings extend the lifespan of the straps and improve their performance in harsh environments.

- Improved End Fitting Designs:

- New end fitting designs offer increased strength and security, reducing the risk of detachment.

- These fittings may incorporate features such as locking mechanisms and swivel joints.

- Color-Coded Straps:

- Some manufacturers are using color-coded straps to indicate working load limits or specific applications.

- This makes it easier for users to select the appropriate strap for the job.

- Recycled Materials:

- There is a growing trend towards using recycled materials in the production of ratchet straps.

- This helps reduce waste and minimize the environmental impact of the industry.

These innovations are driving improvements in cargo securement practices and enhancing the safety and efficiency of transportation operations. According to market research, the demand for advanced tie-down solutions is increasing as companies seek to improve their safety records and reduce cargo damage. At HOW.EDU.VN, our experts stay informed about the latest advancements in ratchet strap technology and can provide guidance on selecting the best solutions for your needs.

Securing cargo safely and effectively requires expertise, and HOW.EDU.VN is here to provide just that. If you’re facing challenges in finding the right ratchet straps or need guidance on securement techniques, our team of over 100 renowned Ph.Ds. is ready to assist. We understand the difficulties in finding reliable, expert advice, and the concerns about the security and accuracy of information.

Contact us today for personalized, in-depth consultations and practical solutions.

Address: 456 Expertise Plaza, Consult City, CA 90210, United States

WhatsApp: +1 (310) 555-1212

Website: HOW.EDU.VN

FAQ: How to Use Ratchet Straps

1. What is the working load limit (WLL) of a ratchet strap?

The working load limit (WLL) is the maximum weight that a ratchet strap is designed to safely secure. Always ensure the WLL meets or exceeds the weight of the cargo.

2. How do I inspect a ratchet strap before use?

Inspect the webbing for cuts, abrasions, or damage. Check the ratchet mechanism for smooth operation and ensure end fittings are not bent or broken.

3. What type of webbing material is best for ratchet straps?

Polyester webbing is commonly used due to its strength, low stretch, and resistance to weather and abrasion.

4. How do I properly thread a ratchet strap?

Insert the strap through the slot in the ratchet spool and pull it through, leaving enough slack to wrap around the cargo.

5. Can I use ratchet straps for lifting?

No, ratchet straps are designed for tie-down purposes only and should never be used for lifting.

6. How often should I inspect ratchet straps during transit?

Regularly check the straps during transit to ensure they remain tight and secure, especially during inclement weather.

7. What should I do with excess webbing after tightening a ratchet strap?

Tie off any excess webbing to prevent it from flapping in the wind. Use rubber bands or tape to keep the webbing secure.

8. How do weather conditions affect ratchet straps?

Rain and humidity can reduce friction, while extreme temperatures can weaken the webbing. Protect straps from UV exposure and adjust tension as needed.

9. Are there legal regulations for using ratchet straps?

Yes, comply with DOT regulations, CVSA guidelines, and other standards to ensure safe and legal cargo securement.

10. How can HOW.EDU.VN help me with ratchet strap usage?

how.edu.vn provides expert guidance, personalized consultations, and comprehensive support to ensure safe and effective cargo securement using ratchet straps. Our team of Ph.Ds. is ready to assist with any questions or challenges you may face.