How Is Plastic Made? This is a question of increasing importance in our world. HOW.EDU.VN offers you a detailed exploration of plastic production, from raw materials to finished products, providing clarity and insight into this complex process. Discover expert guidance to understand plastic manufacturing and sustainable alternatives.

1. Understanding Polymers and Plastics

All plastics are polymers, but not all polymers are plastics. To truly understand how is plastic made, it is essential to clarify what polymers and plastics are.

The terms “polymer” and “monomer” originate from Greek words. “Poly” signifies ‘many,’ “mer” denotes a ‘repeating unit,’ and “mono” means ‘one.’ Therefore, a polymer is essentially constructed from numerous repeating monomer units. These polymers consist of larger molecules created by covalently bonding several monomer units together in chains, akin to pearls on a string.

The term “plastic” is derived from the Latin word “plasticus,” meaning ‘capable of molding,’ and the Greek word “plastikos,” which means ‘fit for molding.’ Plastics refer to high molecular weight organic polymers (whether synthetic or natural) that are combined with other substances.

Plastics are organic polymers with high molecular weight, consisting of various elements such as carbon, hydrogen, oxygen, nitrogen, sulfur, and chlorine. They can also be produced using silicon atoms (known as silicone) in combination with carbon; silicone breast implants or silicone hydrogel for optical lenses are common examples. Plastics consist of a polymeric resin that is often mixed with additives.

“Plasticity” refers to a material’s ability to deform irreversibly without breaking. Plasticity determines whether a polymer can withstand the temperature and pressure during the molding process.

Chemistry enables us to modify various parameters to fine-tune the characteristics of polymers. By using different elements, changing the types of monomers, and rearranging them in different patterns, we can alter the shape, molecular weight, or other chemical and physical properties of the polymer. This allows plastics to be designed with the right properties for specific applications.

2. The Role of Hydrocarbons in Plastic Production

Most plastics used today are derived from hydrocarbons obtained from fossil fuels like crude oil, natural gas, and coal.

2.1 What is a Hydrocarbon?

Hydrocarbons are organic compounds (either aliphatic or aromatic) composed of carbon and hydrogen. Aliphatic hydrocarbons do not have cyclic benzene rings, whereas aromatics do.

Carbon (C, atomic number = 6) has a valency of four, meaning it has four electrons in its outermost shell. It can pair up with four other electrons from any element on the periodic table to form chemical bonds (for hydrocarbons, it will pair with hydrogen). On the other hand, hydrogen (H, with atomic number = 1) has only one electron in the valence shell, so four of these H-atoms are ready to pair up with a C-atom by forming a single bond to give a CH4 molecule. The CH4 molecule is called methane, the simplest hydrocarbon and the first member of the Alkane family. Similarly, if two C-atoms bond together, they can link with up to six H-atoms, with three being on each C-atom, resulting in a chemical formula of CH3-CH3 (or C2H6), known as ethane. The series continues as follows.

Alkane Family: Methane (CH4), ethane (CH3-CH3 or C2H6), propane (CH3-CH2-CH3), butane (CH3-CH2-CH2-CH3), pentane (CH3-CH2-CH2-CH2-CH3), hexane, heptane, octane, nonane, dodecane, undecane, and so on.

It should be noted that this type of bond with carbon and hydrogen is a saturated bond (sigma bond denoted as σ-bond). There can also be an unsaturated bond where a pi bond (π-bond) is present along with a sigma bond, resulting in carbon-carbon double bonds (alkenes), or two π-bonds with a sigma bond, resulting in carbon-carbon triple bonds (alkynes), which depends heavily on the type of hybridization between the elements.

Alkene Family: Ethylene (CH2=CH2 or C2H4), propylene (CH2=CH-CH2), 1-butylene (CH2=CH-CH2-CH3), 2-butylene (CH3-CH=CH-CH3), and so on. (Note that 1-butylene and 2-butylene are isomers of butylene).

Alkyne Hydrocarbons: Ethyne (CH ≡ CH or C2H2), propyne (CH≡C-CH3), 1-butyne (CH≡C-CH2-CH3), 2-butyne (CH3-CH≡CH-CH3), and so on.

2.2 Fossil Fuels: The Origin of Hydrocarbons

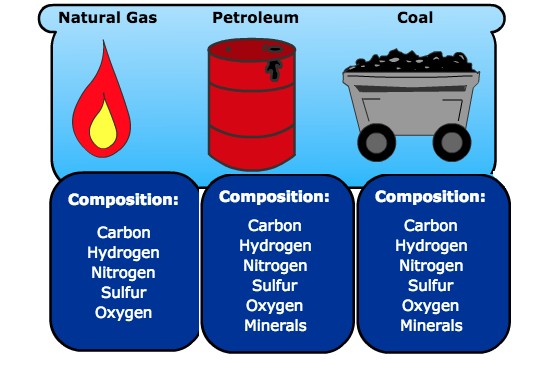

Fossil fuels, primarily crude oil, natural gas, and coal, consist of carbon, hydrogen, nitrogen, sulfur, oxygen, and other minerals. The widely accepted theory is that these hydrocarbons are formed from the remains of living organisms called plankton (tiny plants and animals) that existed during the Jurassic era. Plankton were buried deep beneath heavy layers of sediments in the Earth’s mantle due to compression from enormous heat and pressure. Dead organisms decomposed without oxygen, transforming them into tiny pockets of oil and gas. Crude oil and gas then penetrated the rocks, ultimately accumulating in reservoirs. Oil and natural gas wells are found at the bottom of our oceans and beneath. Coal mainly originated from dead plants.

Figure 2. Elemental composition of fossil fuels

However, scientists have questioned this theory. A recent study in Nature Geoscience from the Carnegie Institution in collaboration with Russian and Swedish colleagues revealed that organic matter may not be the source of heavy hydrocarbons, and that they could already exist deep within the Earth. Experts discovered that ethane and other heavy hydrocarbons could be made if the pressure-temperature conditions can be mimicked with those present deep inside the Earth’s core. This suggests that hydrocarbons can be made in the upper mantle, the layer of Earth between the crust and the core. They demonstrated this by subjecting methane to laser heat-treatment in the upper layer of the Earth, which then transformed it into hydrogen molecules, ethane, propane, petroleum ether, and graphite. The scientists then exposed ethane to the same conditions, which reversibly produced methane. These findings indicate that hydrocarbons might be created naturally without the remains of plants and animals.

3. Creating Synthetic Plastic from Crude Oil: A Step-by-Step Guide

Synthetic plastic is derived from petrochemicals. Once a source of oil beneath the Earth’s surface is identified, holes are drilled through the rocks in the ground to extract the oil. This section details the process of understanding that how is plastic made.

3.1 Extraction of Oil

Oil is pumped from underground to the surface, where tankers transport it to the shore. Oil drilling can also occur under the ocean using support from platforms. Pumps of varying sizes can produce between 5 to 40 liters of oil per stroke.

3.2 Refining of Oil

Oil is transported through pipelines that can be thousands of miles long to an oil refinery. Spillage of oil from the pipeline during transfer can have both immediate and long-term environmental consequences, but safety measures are in place to prevent and minimize this risk.

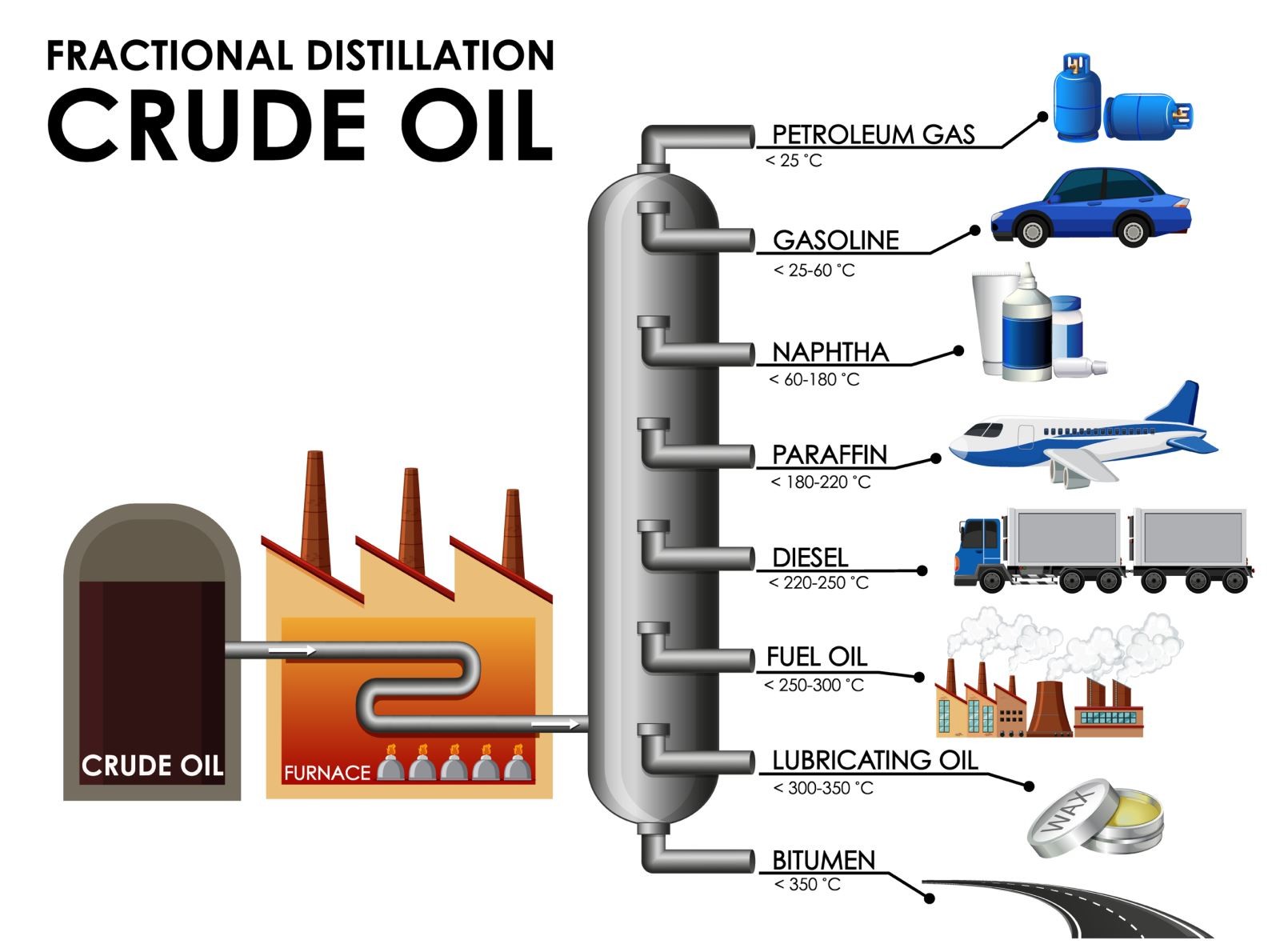

Figure 3: Fractional distillation of crude oil

3.3 Distillation of Crude Oil and Production of Petrochemicals

Crude oil is a mixture of hundreds of hydrocarbons, also containing some solids and some gaseous hydrocarbons dissolved in it from the alkane family (mainly CH4 and C2H6, but it can be C3H8 or C4H10). Crude oil is first heated in a furnace, and the resulting mixture is fed as a vapor to a fractional distillation tower. The fractional distillation column separates the mixture into different compartments called fractions. There is a temperature gradient in the distillation tower, with the top being cooler than the base. The mixture of liquid and vapor fractions is separated in the tower depending on their weight and boiling point (the temperature at which the liquid phase changes into gaseous). When the vapors evaporate and meet a liquid fraction whose temperature is below the boiling point of the vapor, it partially condenses. These vapors of evaporating crude oil condense at different temperatures in the tower. Vapors (gases) of the lightest fractions (gasoline and petroleum gas) flow to the top of the tower, intermediate-weight liquid fractions (kerosene and diesel oil distillates) linger in the middle, heavier liquids (called gas oils) separate lower down, while the heaviest fractions (solids) with the highest boiling points remain at the base of the tower. Each fraction in the column contains hydrocarbons with a similar number of carbon atoms; smaller molecules are towards the top and longer molecules nearer the bottom of the column. In this way, petroleum is decomposed into petroleum gas, gasoline, paraffin (kerosene), naphtha, light oil, heavy oil, etc.

After distillation, the long-chain hydrocarbons are converted into hydrocarbons that can then be turned into essential chemicals used to prepare a wide range of products, from plastics to pharmaceuticals.

Cracking of hydrocarbons is the main process that breaks down complex hydrocarbons into simpler, low relative molecular mass alkenes/alkanes (plus by-products) by applying high temperature and pressure.

Cracking can be performed in two ways: steam cracking and catalytic cracking.

Steam cracking uses high temperature and pressure to break the long chains of hydrocarbons without a catalyst, while catalytic cracking adds a catalyst that allows the process to occur at lower temperatures and pressures.

The raw material used by the petrochemical industry is mainly naphtha and natural gas from oil refining operations in the petrochemical feedstock. Steam cracking uses feedstocks from hydrocarbon mixtures from various fractions, such as reactant gases (ethane, propane, or butane) from natural gas, or liquids (naphtha or gas oil).

.jpg)

Figure 4: Various chemicals obtained from fossil fuel after oil refining.

Naphtha is a mixture of C5 to C10 hydrocarbons obtained from the distillation of crude oil.

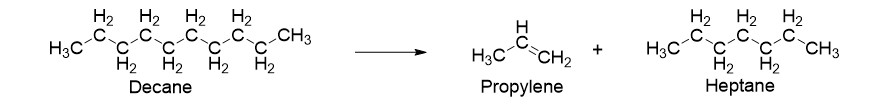

For example, decane hydrocarbon is cracked down into products such as propylene and heptane, where the former is then used to make poly(propylene).

Figure 5. Representation of Cracking of decane to convert into propylene and heptane.

Raw material molecules are converted into monomers such as ethylene, propylene, butene, and others. All these monomers comprise double bonds so that the carbon atoms can subsequently react to form polymers.

Polymerization – Hydrocarbon monomers are then linked together by a chemical polymerization mechanism to produce polymers. The polymerization process generates thick, viscous substances as resins, which are employed to make plastic products. If we consider the case of ethylene monomer, ethylene is a gaseous hydrocarbon. When subjected to heat, pressure, and a certain catalyst, it joins together into long, repeating carbon chains. These joined molecules (polymer) form a plastic resin known as polyethylene (PE).

Production of PE-based plastic – Poly(ethylene) is processed in a factory to make plastic pellets. The pellets are poured into a reactor, melted into a thick liquid, and cast into a mold. The liquid cools down to harden into a solid plastic and produce a finished product. Processing of polymers also includes the addition of plasticizers, dyes, and flame-retardant chemicals.

3.4 Types of Polymerization

Synthetic plastic is made by a reaction known as polymerization, which can be performed in two different ways:

Addition Polymerization: Synthesis includes adding together monomers in a long chain. One monomer connects to the next, and so on, when a catalyst is introduced, in a process known as chain growth polymers, adding one monomer unit at a time. Some addition polymerization reactions are considered to create no side-products, and the reaction can be performed in the vapor phase (i.e., gas phase) dispersed in a liquid. Examples include polyethylene, polypropylene, polyvinyl chloride, and polystyrene.

Condensation Polymerization: In this case, two monomers combine to form a dimer (two units) by releasing a byproduct. Dimers can then join to form tetramers (four units), and so on. These byproducts must be removed for the reaction to succeed. The most common byproduct is water, which is treated and disposed of easily. Byproducts can also be valuable raw materials that are recycled back into the feedstream.

Examples include nylon (polyamide), polyester, and polyurethane.

4. Naphtha’s Role in Plastic Creation

Plastic is often created from naphtha. For example, ethylene and propylene are the main raw materials for oil-based plastic derived from naphtha.

4.1 What is Naphtha?

There are different types of naphtha. The term describes a group of volatile mixtures of liquid hydrocarbons obtained by the distillation of crude oil. It is a mixture of C5 to C10 hydrocarbons.

Naphtha is thermally decomposed at high temperatures (~800 °C) in a steam cracker in the presence of water vapor, where it splits into light hydrocarbons known as major intermediaries. These are olefins and aromatics. Among the olefins, there are C2 (ethylene), C3 (propylene), and C4 (butane and butadiene). The aromatics consist of benzene, toluene, and xylene. These small molecules are linked together into long molecular chains called polymers. When a polymer comes out of the chemical factory, it is not yet in the form of plastic—it is in the form of granules or powders (or liquids). Before it can become an everyday-use plastic, it needs to undergo a series of transformations. It is kneaded, heated, melted, and cooled into objects of various shapes, sizes, colors, and with precise properties according to the processing tubes.

For instance, for the polymerization of ethylene into polyethylene (PE), initiators are added to start the chain reaction. Only after the formation of PE is it sent for processing by adding chemicals (antioxidants and stabilizers). After that, an extruder converts PE into strings, and grinders convert it into PE pellets. Factories then melt them into final products.

5. Key Ingredients in Plastic Manufacturing

The main ingredient in most plastic materials is a derivative from crude oil and natural gas.

There are many different types of plastics—clear, cloudy, solid color, flexible, rigid, soft, etc.

Plastic products are often a polymer resin mixed with a blend of additives. These additives are important because each one is used to provide plastic with targeted optimum properties, such as toughness, flexibility, elasticity, color, or to make them safer and more hygienic for a particular application.

The type of plastic a product is made from can sometimes be identified by looking at the number at the bottom of plastic containers. Some of the main types of plastic and the parent monomer are given below (Table 1). This table shows the types of plastic and the monomers that make up the plastic.

Table 1. Main polymer types, monomers, and their chemical structures

| Resin identification code | Polymers | Monomers |

|---|---|---|

| ♳ PETE | Polyethylene terephthalate (PET) | Ethylene glycol and Dimethyl terephthalate |

| ♴ HDPE | High-density polyethylene (HDPE) | Ethylene (CH2=CH2) *(lesser branching between polymer chains) |

| ♵ PVC | Polyvinyl chloride (PVC) | Vinyl chloride (CH2=CH-Cl) |

| ♶ LDPE | Low-density polyethylene (LDPE) | Ethylene (CH2=CH2) *(excessive branching) |

| ♷ PP | Polypropylene (PP) | Propylene (CH3-CH=CH2) |

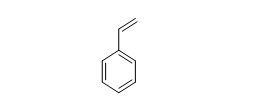

| ♸ PS | Polystyrene (PS) | Styrene |

| ♹ Others | Other plastics including acrylic, polycarbonate, polylactic acid (PLA), fibers, nylon | Different monomers are used for a particular polymer. For instance, PLA is made from Lactic acid |

*The monomer used in LDPE and HDPE is ethylene, but there is a difference in the degree of branching.

6. The History of Plastic: From Bioplastics to Synthetics

Understanding that how is plastic made also involves knowing its history. Mesoamerican cultures (Olmec, Maya, Aztecs, 1500 BCE) used natural latex and rubber to make containers and clothes water-resistant.

Alexander Parkes (UK, 1856) patented the first man-made bioplastic, called Parkesine, made from cellulose nitrate. Parkesine was a hard, flexible, and transparent plastic. John Wesley Hyatt (US, 1860s) made a fortune with Parkes’ invention. The Hyatt brothers improved the malleability of cellulose nitrate by adding camphor and renamed the plastic Celluloid. The aim was to produce billiard balls, which until then were made from ivory. The invention is considered the earliest example of man-made bioplastic by many.

The first truly synthetic plastic was Bakelite, made from phenol and formaldehyde resin. Leo Baekeland (Belgium, 1906) invented Bakelite, which was coined as a ‘National Historic Chemical Landmark’ because it completely revolutionized every industry in modern life. It has high resistance to electricity, heat, and chemicals. It has non-conducting properties, which are extremely essential when designing electronic devices such as radio and telephone casings.

7. Materials Used Before Plastic

Before the advent of plastic, materials such as wood, metal, glass, ceramic, and animal-derived materials like horn, bone, and leather were commonly used.

For storage, moldable clays (pottery) mixed with glass were used, which meant the containers were often heavy and fragile.

Natural materials from the bark of the rubber tree—gum (latex resin)—came into existence; the mix was sticky and moldable but not useful for storage.

In the 18th century, Charles Goodyear accidentally discovered rubber: he added sulfur to hot crude rubber, which reacted and made the rubber resilient, which upon cooling became elastic—that is, it had the property to snap back into its original shape.

8. Sustainable Alternatives: Making Plastic Without Oil

Understanding how is plastic made also involves knowing sustainable alternatives. Yes, it is possible to create plastic from sources other than oil.

Although crude oil is the principal source of carbon for modern plastic, an array of variants are manufactured from renewable materials. Plastic made without oil is marketed as biobased plastic or bioplastics. These are made from renewable biomass such as:

- Lignin, cellulose, and hemicellulose

- Terpenes

- Vegetable fats and oils

- Carbohydrates (sugars from sugarcane, etc.)

- Recycled food waste

- Bacteria

However, it should be noted that bioplastics are not automatically a more sustainable alternative in every case. Bioplastics differ as per the ways in which they break down, and bioplastics also, as any material, require resources in their production.

For example, bioplastics such as PLA represent a biodegradable material that will degrade under certain environmental conditions but may not biodegrade in all sorts of climates. Therefore, a waste stream of PLA-based plastic is required. In the case of PLA, it is a sensitive polyester that begins to degrade during the recycling procedure and can end up contaminating the existing plastic recycling stream.

But bioplastics can have many uses when designed with a proper waste stream in mind.

Bioplastics are potential materials for the fabrication of single-use plastic such as that required to make biodegradable bottles and packaging films. For instance, in 2019, a researcher from the University of Sussex created a transparent plastic film from fish-skin waste and algae called MarinaTex. Biopolymers have also been investigated for medical applications, such as controlled drug release, drug packaging, and absorbable surgical sutures.

Maurice Lemoigne (France, 1926) discovered the first bioplastics made from bacteria, polyhydroxybutyrate (PHB), from the bacterium Bacillus megaterium. As bacteria consume sugars, they produce the polymers. The importance of Lemoigne’s invention was overlooked until the oil crisis hit in the mid-1970s, spurring interest in discovering substitutes for petroleum-based products.

Henry Ford (US, 1940) used bioplastics made from soybeans for some car parts. Ford discontinued the use of soy plastics after World War II because of the surplus of inexpensive oil supplies.

The developments in metabolic and genetic engineering have expanded the research on bioplastics, and applications for numerous types of bioplastics had become established, particularly PHB and polyhydroxyalkanoate (PHA), although there are many other interesting developments occurring all the time.

9. Expert Insights from HOW.EDU.VN on Plastic Manufacturing

9.1 The Expertise You Need

Understanding the intricacies of how plastic is made requires deep knowledge and experience. At HOW.EDU.VN, we connect you with leading Ph.D. experts who can provide comprehensive insights and solutions related to plastic manufacturing and sustainability.

9.2 Navigating Challenges in Plastic Production

Many businesses and individuals face challenges in understanding and optimizing plastic production processes. Common issues include:

- Complexity of the Manufacturing Process: Understanding the detailed steps from raw material extraction to finished product.

- Sustainability Concerns: Finding eco-friendly alternatives and managing waste effectively.

- Regulatory Compliance: Keeping up with evolving environmental regulations.

- Cost Optimization: Balancing production costs with quality and sustainability.

9.3 How HOW.EDU.VN Can Help

Our Ph.D. experts offer specialized consulting services to address these challenges. We provide:

- In-depth Process Analysis: Evaluating and optimizing your plastic manufacturing processes for efficiency and sustainability.

- Sustainable Material Guidance: Identifying and implementing bio-based and biodegradable alternatives.

- Regulatory Compliance Support: Ensuring your operations meet all relevant environmental standards.

- Cost-Effective Solutions: Helping you reduce production costs while maintaining quality and environmental responsibility.

9.4 Benefits of Consulting with Our Experts

By consulting with our Ph.D. experts, you can:

- Gain Clarity: Understand the complex processes involved in plastic manufacturing.

- Improve Sustainability: Adopt environmentally friendly practices and materials.

- Ensure Compliance: Meet all regulatory requirements.

- Optimize Costs: Reduce expenses and increase profitability.

10. The Advantages of Seeking Advice from HOW.EDU.VN’s Team of Over 100 Doctors

10.1 Personalized Solutions

At HOW.EDU.VN, we recognize that every client’s needs are unique. Our Ph.D. experts provide customized solutions tailored to your specific challenges and goals.

10.2 Up-to-Date Knowledge

Our team stays current with the latest advancements and trends in plastic manufacturing and sustainability, ensuring you receive the most relevant and effective advice.

10.3 Comprehensive Support

From initial consultation to implementation, we offer ongoing support to ensure your success. Our experts are committed to helping you achieve your objectives.

10.4 Proven Results

Our clients have seen significant improvements in their plastic manufacturing processes, sustainability practices, and overall business performance. We are dedicated to delivering measurable results.

11. Why Choose HOW.EDU.VN for Expert Consulting?

11.1 Access to Top-Tier Experts

HOW.EDU.VN provides access to a diverse network of Ph.D. experts with extensive experience in plastic manufacturing and sustainability.

11.2 Streamlined Consultation Process

We make it easy to connect with the right expert and get the advice you need quickly and efficiently.

11.3 Confidential and Secure

We prioritize the confidentiality and security of your information, ensuring a safe and trustworthy consulting experience.

11.4 Commitment to Excellence

HOW.EDU.VN is committed to providing high-quality consulting services that exceed your expectations and drive meaningful results.

12. Real-World Impact: Success Stories

12.1 Case Study 1: Optimizing Production Efficiency

A plastic manufacturing company was struggling with low production efficiency and high waste. They sought advice from one of our Ph.D. experts, who analyzed their processes and recommended specific improvements. As a result, the company increased production efficiency by 20% and reduced waste by 15%.

12.2 Case Study 2: Transitioning to Sustainable Materials

A packaging company wanted to transition to more sustainable materials but didn’t know where to start. Our experts guided them in selecting bio-based alternatives and implementing eco-friendly practices. The company successfully transitioned 50% of their product line to sustainable materials, enhancing their brand image and attracting environmentally conscious customers.

12.3 Case Study 3: Ensuring Regulatory Compliance

A plastics manufacturer was facing challenges in meeting new environmental regulations. Our experts provided comprehensive support in understanding and implementing the necessary changes. The company successfully achieved compliance, avoiding costly penalties and maintaining their competitive edge.

13. The Future of Plastic Manufacturing: Trends and Innovations

13.1 Advancements in Bio-Based Plastics

Continued research and development are leading to more sustainable and high-performance bio-based plastics.

13.2 Enhanced Recycling Technologies

Innovations in recycling technologies are improving the efficiency and effectiveness of plastic recycling processes.

13.3 Circular Economy Models

The adoption of circular economy models is promoting the reuse and repurposing of plastic materials, reducing waste and environmental impact.

13.4 Smart Plastics

The development of smart plastics with advanced functionalities is opening up new possibilities for various applications.

14. Frequently Asked Questions (FAQs) About Plastic Manufacturing

Q1: What are the main raw materials used to make plastic?

A: The main raw materials are crude oil, natural gas, and renewable biomass such as plant-based oils and starches.

Q2: What is the difference between synthetic and bio-based plastics?

A: Synthetic plastics are derived from fossil fuels, while bio-based plastics are made from renewable resources.

Q3: How can I make my plastic manufacturing process more sustainable?

A: You can use bio-based materials, improve recycling processes, and adopt circular economy models.

Q4: What are the environmental regulations I need to comply with?

A: Regulations vary by region, but common ones include waste management, emissions control, and material restrictions.

Q5: How can I reduce the cost of plastic manufacturing?

A: Optimize production processes, use cost-effective materials, and implement efficient waste management practices.

Q6: What are the benefits of using bio-based plastics?

A: Reduced dependence on fossil fuels, lower carbon footprint, and potential biodegradability.

Q7: How do I choose the right type of plastic for my product?

A: Consider factors such as strength, flexibility, temperature resistance, and environmental impact.

Q8: What are the latest innovations in plastic recycling?

A: Chemical recycling, advanced sorting technologies, and improved collection methods.

Q9: How can HOW.EDU.VN help with my plastic manufacturing challenges?

A: We connect you with Ph.D. experts who can provide customized solutions, in-depth analysis, and ongoing support.

Q10: Where can I find reliable information about plastic manufacturing and sustainability?

A: HOW.EDU.VN offers expert insights, articles, and consulting services to help you stay informed and make better decisions.

15. Take Action: Consult with a Ph.D. Expert Today

Are you ready to take your plastic manufacturing process to the next level? Do you need expert guidance on sustainability, compliance, or cost optimization? Contact HOW.EDU.VN today and connect with a Ph.D. expert who can help you achieve your goals.

15.1 Contact Information

- Address: 456 Expertise Plaza, Consult City, CA 90210, United States

- WhatsApp: +1 (310) 555-1212

- Website: HOW.EDU.VN

Don’t let challenges hold you back. Let our team of over 100 Ph.D. experts provide the solutions you need. Contact us now and start your journey toward a more efficient, sustainable, and successful future.

By understanding how is plastic made and leveraging expert advice, you can address challenges, optimize processes, and drive meaningful results.

This comprehensive guide provides a detailed exploration of how is plastic made, covering the entire process from raw materials to sustainable alternatives. By leveraging the expertise available at how.edu.vn, businesses and individuals can navigate the complexities of plastic manufacturing and achieve their goals.