Knowing How Much Do T Shirts Weigh is essential for businesses and individuals alike, especially when dealing with shipping costs and inventory management. HOW.EDU.VN understands the importance of accurate information, offering expert insights to help you navigate the complexities of garment weight. This guide explores the various factors influencing t-shirt weight, from fabric type to size, providing solutions to estimate and manage these weights effectively. Explore weight variations, packaging considerations, and expert tips for streamlining your shipping process and for further assistance, consult our team of experts at HOW.EDU.VN.

1. Understanding T-Shirt Weight: An Overview

The weight of a t-shirt is influenced by several factors, including the type of fabric used, the size of the shirt, and the manufacturing process. Understanding these elements can provide a clearer picture of what to expect when calculating shipping costs or managing inventory.

1.1. Factors Influencing T-Shirt Weight

Several key factors determine the weight of a t-shirt. These include the type of fabric, the size of the garment, and the specific manufacturing processes used.

- Fabric Type: The material used plays a significant role. Cotton, polyester, and blends each have different densities, affecting the overall weight. For instance, a 100% cotton shirt will generally weigh more than a polyester blend.

- Size of the Garment: Obviously, larger sizes require more material, leading to a heavier t-shirt. A small t-shirt will weigh considerably less than an extra-large one.

- Manufacturing Process: The way a t-shirt is constructed can also impact its weight. This includes the thickness of the fabric and any additional features, such as pockets or reinforced seams.

1.2. Why T-Shirt Weight Matters

Understanding t-shirt weight is crucial for various reasons, especially for businesses involved in e-commerce or bulk shipments.

- Shipping Costs: Accurate weight measurements are essential for calculating shipping costs. Even small differences can significantly impact the overall expense, especially for international shipments.

- Inventory Management: Knowing the weight of your products helps in efficient inventory management. It allows for better planning of storage and logistics, reducing potential errors and costs.

- Customer Satisfaction: Providing accurate shipping information to customers enhances their satisfaction. Transparency in shipping costs builds trust and encourages repeat business.

- Budgeting: Understanding t-shirt weights helps businesses budget effectively for shipping expenses, especially important for small businesses with tight margins.

1.3. Common Units of Measurement

T-shirt weight is typically measured in grams (g) or ounces (oz). Here’s a quick conversion to keep in mind:

- 1 ounce (oz) ≈ 28.35 grams (g)

- 1 gram (g) ≈ 0.035 ounces (oz)

These conversions are useful when dealing with different measurement systems, ensuring accurate calculations regardless of the unit used.

2. Detailed Analysis of T-Shirt Weights by Brand and Style

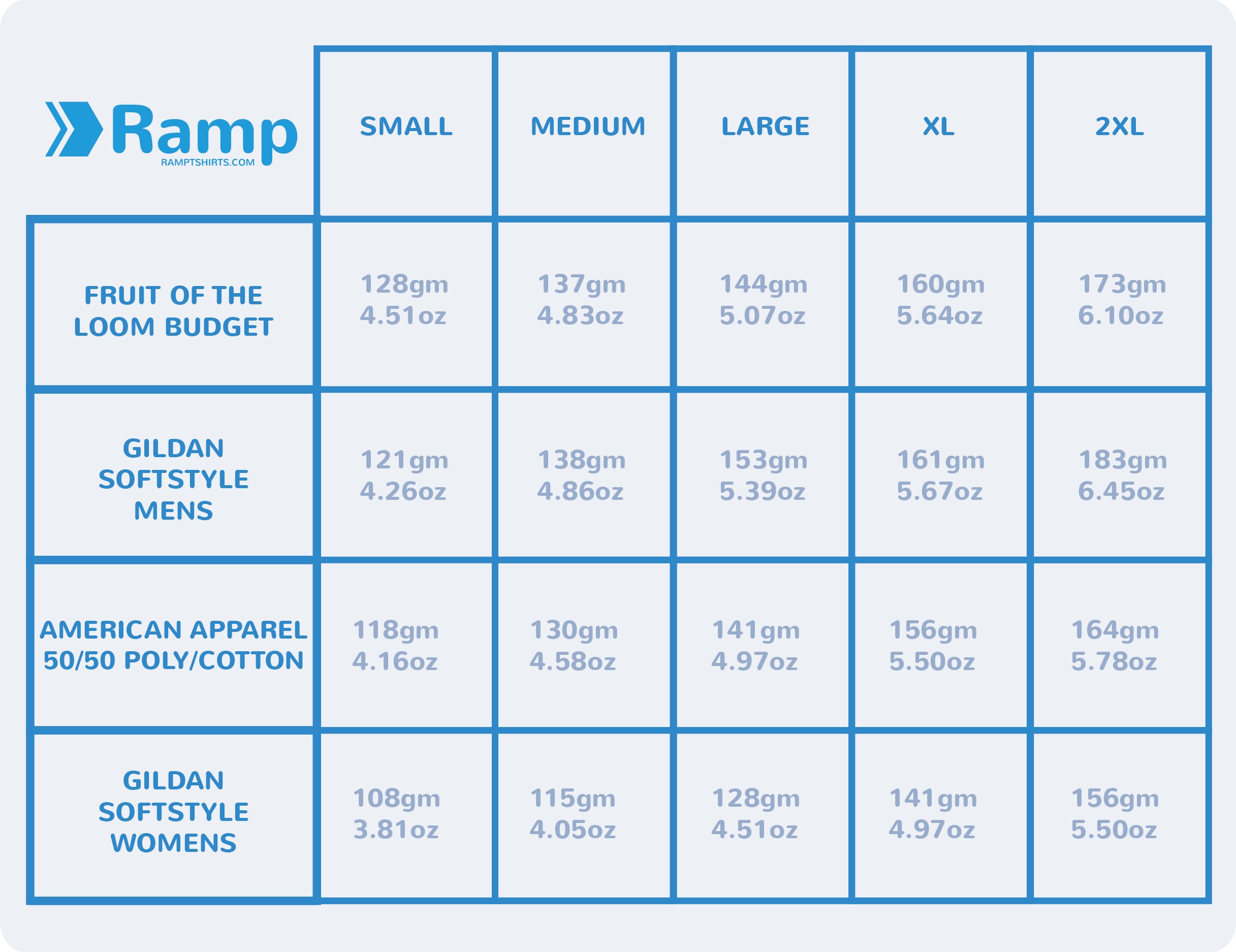

Different brands and styles of t-shirts vary in weight due to the materials used and the construction techniques. Here’s a detailed look at some popular brands and their average t-shirt weights.

2.1. Popular T-Shirt Brands and Their Weights

| Brand | Style | Size | Approximate Weight (grams) | Approximate Weight (ounces) |

|---|---|---|---|---|

| Gildan | Heavy Cotton | Small | 150 | 5.3 |

| Gildan | Heavy Cotton | Medium | 170 | 6.0 |

| Gildan | Heavy Cotton | Large | 190 | 6.7 |

| Gildan | Softstyle | Small | 130 | 4.6 |

| Gildan | Softstyle | Medium | 150 | 5.3 |

| Gildan | Softstyle | Large | 170 | 6.0 |

| Fruit of the Loom | Heavy Cotton | Small | 140 | 4.9 |

| Fruit of the Loom | Heavy Cotton | Medium | 160 | 5.6 |

| Fruit of the Loom | Heavy Cotton | Large | 180 | 6.3 |

| Fruit of the Loom | Value Weight | Small | 120 | 4.2 |

| Fruit of the Loom | Value Weight | Medium | 140 | 4.9 |

| Fruit of the Loom | Value Weight | Large | 160 | 5.6 |

| Hanes | Beefy-T | Small | 160 | 5.6 |

| Hanes | Beefy-T | Medium | 180 | 6.3 |

| Hanes | Beefy-T | Large | 200 | 7.0 |

| Hanes | Tagless | Small | 140 | 4.9 |

| Hanes | Tagless | Medium | 160 | 5.6 |

| Hanes | Tagless | Large | 180 | 6.3 |

| American Apparel | 2001 | Small | 110 | 3.9 |

| American Apparel | 2001 | Medium | 130 | 4.6 |

| American Apparel | 2001 | Large | 150 | 5.3 |

| Next Level Apparel | 3600 | Small | 100 | 3.5 |

| Next Level Apparel | 3600 | Medium | 120 | 4.2 |

| Next Level Apparel | 3600 | Large | 140 | 4.9 |

| Bella + Canvas | 3001 | Small | 90 | 3.2 |

| Bella + Canvas | 3001 | Medium | 110 | 3.9 |

| Bella + Canvas | 3001 | Large | 130 | 4.6 |

Note: Weights are approximate and can vary slightly due to manufacturing tolerances.

2.2. Weight Variations by T-Shirt Style

Different styles of t-shirts, such as crew neck, V-neck, and long-sleeve, also contribute to weight variations.

- Crew Neck vs. V-Neck: V-neck t-shirts generally weigh slightly less than crew neck shirts because they use a bit less fabric around the neckline.

- Long-Sleeve vs. Short-Sleeve: Long-sleeve t-shirts naturally weigh more due to the added fabric in the sleeves. This can be a significant difference, especially in heavier materials.

- Fitted vs. Relaxed Fit: Fitted t-shirts might use slightly less fabric compared to relaxed fit styles, leading to a small difference in weight.

2.3. Impact of Fabric Composition on Weight

The composition of the fabric is a primary factor influencing the weight of a t-shirt. Different materials have different densities, affecting the overall weight.

- 100% Cotton: Known for its comfort and breathability, 100% cotton t-shirts tend to be heavier due to the density of the cotton fibers.

- Polyester: Polyester is a lightweight synthetic fabric. T-shirts made from 100% polyester are generally lighter than cotton.

- Blends (e.g., Cotton-Polyester): Blended fabrics offer a balance of properties from each material. Cotton-polyester blends usually have a weight between that of pure cotton and pure polyester.

- Tri-Blends (e.g., Cotton-Polyester-Rayon): These blends combine the characteristics of three different fibers. Tri-blend t-shirts are often lightweight and have a soft feel.

- Specialty Fabrics: Fabrics like bamboo, modal, or linen can also influence the weight. Bamboo and modal are known for being lightweight and soft, while linen can vary but is generally lighter than cotton.

2.4. Heather Finishes and Their Effect on Weight

Heather finishes can subtly affect the weight of a t-shirt. Heathered fabrics are created by blending different colored fibers, which can sometimes result in a slightly lighter weight compared to solid colors.

- Heather vs. Solid Colors: Heathered t-shirts tend to be a couple of grams lighter than their solid-colored counterparts due to the blending process.

- Type of Heather: Different types of heather finishes, such as triblend heather or standard heather, may have slight variations in weight depending on the specific blend of fibers used.

3. Practical Guide to Weighing T-Shirts

Weighing t-shirts accurately is essential for managing shipping costs and inventory. Here’s a practical guide to help you get precise measurements.

3.1. Tools and Equipment Needed

To accurately weigh t-shirts, you’ll need a few basic tools:

- Digital Scale: A digital scale is the most accurate tool for measuring weight. Look for one that can measure in grams and ounces. A scale with a precision of at least 1 gram or 0.1 ounces is ideal.

- Packaging Materials: Have the packaging materials you typically use on hand, such as plastic mailbags or boxes. This allows you to weigh the complete package for accurate shipping calculations.

- Notebook and Pen: Keep a notebook and pen nearby to record the weights as you measure them. Alternatively, use a spreadsheet on a computer or tablet.

3.2. Step-by-Step Instructions for Weighing T-Shirts

Follow these steps to accurately weigh your t-shirts:

- Calibrate the Scale: Before you begin, calibrate your digital scale to ensure accurate readings. Most digital scales have a calibration function.

- Prepare the T-Shirt: Fold the t-shirt neatly as you would when packaging it for shipping.

- Place the T-Shirt on the Scale: Put the folded t-shirt on the center of the scale platform.

- Record the Weight: Wait for the scale to stabilize and record the weight in grams and/or ounces.

- Include Packaging: If you’re weighing for shipping purposes, place the folded t-shirt inside the packaging (e.g., a plastic mailbag) and weigh the complete package. Record this weight as well.

- Repeat for Multiple Items: Weigh several t-shirts of the same style and size to ensure consistency. Calculate the average weight to use for your records.

3.3. Tips for Accurate Measurements

- Use a High-Quality Scale: Invest in a good quality digital scale to ensure precise measurements.

- Check Scale Placement: Place the scale on a flat, stable surface to avoid inaccurate readings.

- Tare Function: Use the tare function on the scale to zero out the weight of any containers or packaging materials before adding the t-shirt.

- Consistent Folding: Fold each t-shirt in the same way to maintain consistency in weight measurements.

- Account for Variations: Be aware that there can be slight variations in weight due to manufacturing tolerances or humidity. Weighing multiple items and calculating the average can help mitigate these discrepancies.

- Regular Calibration: Calibrate your scale regularly to maintain accuracy, especially if it is moved frequently or used in different environments.

3.4. Common Mistakes to Avoid

- Ignoring Packaging Weight: For shipping calculations, it’s crucial to include the weight of the packaging materials.

- Using an Uncalibrated Scale: An uncalibrated scale can lead to significant errors in weight measurements.

- Assuming All T-Shirts Are the Same Weight: Even t-shirts of the same size and style can have slight weight variations.

- Not Accounting for Humidity: Humidity can affect the weight of fabric. Weighing t-shirts in a dry environment can provide more consistent results.

4. Impact of Packaging on Overall Shipping Weight

Packaging materials significantly contribute to the overall weight of a shipment. Understanding the weight of different packaging options can help optimize shipping costs.

4.1. Types of Packaging Materials and Their Weights

- Plastic Mailbags: These are lightweight and waterproof, making them a popular choice for shipping individual t-shirts. A typical plastic mailbag weighs around 15-30 grams (0.5-1 ounce).

- Cardboard Boxes: Cardboard boxes offer more protection but weigh considerably more than plastic mailbags. The weight varies depending on the size and thickness of the cardboard, ranging from 50 grams (1.8 ounces) for a small box to several hundred grams for a larger one.

- Bubble Mailers: These provide added cushioning and weigh more than standard plastic mailbags. A bubble mailer can weigh between 30-50 grams (1-1.8 ounces).

- Packing Tape: The weight of packing tape is minimal but should still be considered, especially for bulk shipments. A roll of packing tape can add a few grams per package.

- Packing Peanuts/Bubble Wrap: If you’re using packing peanuts or bubble wrap for added protection, factor in their weight. These materials can add 10-50 grams (0.35-1.8 ounces) depending on the quantity used.

4.2. How to Choose the Right Packaging to Minimize Weight

- Assess Protection Needs: Determine the level of protection needed for your t-shirts. If they are not fragile, a lightweight plastic mailbag may suffice. For more delicate items or larger shipments, a cardboard box with cushioning might be necessary.

- Consider Size: Choose the smallest possible packaging size that can comfortably fit the t-shirt. Excess space adds unnecessary weight and can increase shipping costs.

- Opt for Lightweight Materials: When possible, select lightweight packaging materials. For example, use thin cardboard boxes instead of thick ones, or choose plastic mailbags over bubble mailers.

- Compare Options: Weigh different packaging options with the t-shirt inside to determine the lightest combination.

- Negotiate with Suppliers: If you ship in bulk, negotiate with packaging suppliers to get lighter materials or custom-sized boxes.

4.3. Examples of Packaging Weights

| Packaging Material | Dimensions (approx.) | Approximate Weight (grams) | Approximate Weight (ounces) |

|---|---|---|---|

| Plastic Mailbag | 250mm x 350mm | 20 | 0.7 |

| Small Cardboard Box | 200mm x 150mm x 100mm | 75 | 2.6 |

| Bubble Mailer | 250mm x 350mm | 40 | 1.4 |

| Packing Tape (per meter) | N/A | 2 | 0.07 |

4.4. Optimizing Packaging for Cost-Effective Shipping

- Consolidate Shipments: When possible, combine multiple items into a single shipment to reduce packaging costs and overall weight.

- Flat Packaging: Flatten t-shirts as much as possible to reduce the overall size of the package. This can sometimes qualify the shipment for lower shipping rates.

- Remove Excess Material: Trim any excess material from packaging to minimize weight.

- Use Automated Packaging Solutions: For high-volume shipping, consider investing in automated packaging solutions that can efficiently package items with minimal material.

- Regularly Review Packaging: Periodically review your packaging methods to identify opportunities for optimization and cost reduction.

5. How T-Shirt Weight Affects Shipping Costs

T-shirt weight directly impacts shipping costs, making it essential for businesses to understand how different carriers calculate rates.

5.1. How Shipping Carriers Calculate Rates

Shipping carriers like USPS, UPS, FedEx, and DHL use several factors to calculate shipping rates:

- Weight: The weight of the package is a primary factor. Carriers often have tiered pricing based on weight ranges.

- Dimensions: The size of the package also matters. Carriers use dimensional weight (DIM weight) to calculate the cost for packages that are large relative to their weight. DIM weight is calculated by multiplying the length, width, and height of the package and dividing by a DIM divisor (which varies by carrier).

- Destination: The distance the package travels affects the shipping cost. Rates are typically higher for international shipments.

- Shipping Speed: Faster shipping options (e.g., express or overnight) come at a premium.

- Additional Services: Extra services like insurance, tracking, or signature confirmation can add to the cost.

5.2. Comparing Shipping Rates from Different Carriers

To compare shipping rates effectively:

- Use Online Calculators: Most carriers have online shipping calculators that allow you to input the weight, dimensions, and destination to get an estimated cost.

- Consider Flat Rate Options: Some carriers offer flat rate shipping for packages that fit into specific box sizes, regardless of weight (up to a certain limit). This can be a cost-effective option for heavier t-shirts.

- Negotiate Rates: If you ship in high volumes, negotiate rates with carriers. Many carriers offer discounted rates for businesses with significant shipping volume.

- Use Shipping Software: Shipping software can help you compare rates from multiple carriers simultaneously, streamlining the process and ensuring you get the best deal.

5.3. Strategies for Reducing Shipping Costs

- Optimize Packaging: Use the smallest and lightest packaging possible to reduce weight and dimensions.

- Consolidate Shipments: Combine multiple orders into a single shipment when feasible.

- Choose Slower Shipping Speeds: Opt for slower shipping speeds if the customer doesn’t need the item urgently.

- Leverage Regional Carriers: Consider using regional carriers, which may offer lower rates for local deliveries.

- Take Advantage of Free Shipping: Offer free shipping to customers by building the shipping cost into the product price or setting a minimum order value.

- Use Carrier Discounts: Take advantage of carrier discounts for online postage, prepaid labels, or specific shipping lanes.

5.4. Real-World Examples of Shipping Cost Savings

- Example 1: A small business reduces its average shipping cost by 15% by switching from cardboard boxes to plastic mailbags for shipping t-shirts.

- Example 2: An e-commerce store negotiates a discounted rate with a carrier for shipping over 100 packages per month, resulting in a 10% reduction in shipping expenses.

- Example 3: A clothing company consolidates multiple small orders into fewer larger shipments, saving on packaging materials and reducing shipping costs by 20%.

6. T-Shirt Weight and Customs Regulations

International shipping involves navigating customs regulations, where t-shirt weight can play a crucial role in determining duties and taxes.

6.1. Understanding Customs Duties and Taxes

Customs duties and taxes are fees imposed by governments on imported goods. These fees vary depending on the country of origin, the type of goods, and their value. Key factors influencing customs duties and taxes include:

- Declared Value: The value of the t-shirts as stated on the customs declaration form.

- Harmonized System (HS) Code: A standardized system of names and numbers used to classify traded products. The HS code for t-shirts helps customs officials determine the applicable duty rate.

- Country of Origin: The country where the t-shirts were manufactured. Some countries have preferential trade agreements that can reduce or eliminate duties.

- Weight: The weight of the shipment can affect the shipping cost, which in turn can influence the total value used to calculate duties and taxes.

6.2. How T-Shirt Weight Affects Import Duties

While the weight of the t-shirts may not directly determine the duty rate, it can impact the overall shipping cost, which is sometimes included in the value used to calculate duties. Additionally, some countries may have specific weight-based regulations or fees.

- Shipping Cost Calculation: Higher weight can lead to higher shipping costs, increasing the total value of the shipment.

- Weight Limits: Some countries have weight limits for certain types of shipments. Exceeding these limits can result in additional fees or delays.

- Inspection Fees: Heavier shipments may be subject to more thorough inspections, which can incur additional fees.

6.3. Tips for Complying with Customs Regulations

- Accurate Documentation: Ensure all customs documents, including the commercial invoice and packing list, are accurate and complete. Include a detailed description of the t-shirts, their value, and the country of origin.

- Correct HS Code: Use the correct HS code for t-shirts to avoid misclassification and potential penalties. Consult with a customs broker or refer to the Harmonized System Explanatory Notes for guidance.

- Declare Value Accurately: Declare the true value of the t-shirts to avoid issues with customs authorities. Underreporting the value can result in fines and delays.

- Check for Trade Agreements: Determine if there are any trade agreements between the country of origin and the destination country that could reduce or eliminate duties.

- Use a Customs Broker: Consider using a customs broker to help navigate the complexities of customs regulations. A broker can ensure compliance and expedite the clearance process.

- Stay Informed: Keep up-to-date with the latest customs regulations and requirements for each country you ship to.

6.4. Case Studies of Customs Compliance

- Case Study 1: A clothing company avoids customs delays by accurately declaring the value and HS code for a shipment of t-shirts to Europe. By working with a customs broker, they ensure compliance with all EU regulations.

- Case Study 2: An e-commerce store leverages a free trade agreement between the United States and Canada to eliminate duties on t-shirts manufactured in the US. This results in significant cost savings and increased competitiveness in the Canadian market.

7. Optimizing T-Shirt Designs to Reduce Weight

While fabric and size are primary factors, the design of a t-shirt can also influence its weight. Here’s how to optimize designs to minimize weight.

7.1. Impact of Print Size and Type on Weight

- Print Size: Large prints can add weight to a t-shirt due to the added ink. Minimizing the size of the print can reduce the overall weight.

- Print Type: Different printing methods use varying amounts of ink. Screen printing, for example, typically uses more ink than direct-to-garment (DTG) printing.

- Number of Colors: Each color in a screen-printed design requires a separate layer of ink. Reducing the number of colors can decrease the weight and cost of the print.

7.2. Lightweight Printing Techniques

- Direct-to-Garment (DTG) Printing: DTG printing applies ink directly to the fabric, using less ink than screen printing. This method is ideal for complex designs with many colors.

- Water-Based Inks: Water-based inks are lighter than traditional plastisol inks. They also have a softer feel and are more environmentally friendly.

- Discharge Printing: Discharge printing removes the dye from the fabric and replaces it with the desired color. This results in a very soft print with minimal added weight.

- Sublimation: Sublimation is a process that dyes the fabric with the design, resulting in a very lightweight and durable print. This method is best suited for polyester fabrics.

7.3. Design Strategies for Lighter T-Shirts

- Minimalist Designs: Opt for simple, minimalist designs that use less ink.

- Strategic Print Placement: Place prints in areas that require less ink, such as the upper chest or sleeve.

- Avoid Heavy Coverage: Avoid designs with large areas of solid ink coverage. Instead, use patterns or textures that allow the fabric to show through.

- Use Lightweight Fonts: Choose lightweight fonts for text-based designs to reduce the amount of ink needed.

- Consider Negative Space: Incorporate negative space into your designs to minimize ink usage and create visually appealing graphics.

7.4. Examples of Weight-Optimized Designs

- Example 1: A clothing brand switches from screen printing to DTG printing for its t-shirt designs, reducing the average weight of the prints by 10%.

- Example 2: An e-commerce store redesigns its t-shirt graphics to use less ink and incorporates water-based inks, resulting in lighter and more eco-friendly products.

- Example 3: A custom apparel company creates minimalist designs with strategic print placement, reducing ink usage and creating visually appealing t-shirts with lower weights.

8. Expert Tips for Managing T-Shirt Weight in Your Business

Efficiently managing t-shirt weight is crucial for optimizing shipping costs and streamlining operations. Here are some expert tips to help you effectively manage t-shirt weight in your business.

8.1. Creating a Weight Database for Your Products

- Measure Each Item: Weigh each t-shirt style and size in your inventory and record the weight in a database.

- Include Packaging: Weigh the t-shirts with their packaging materials and record these weights as well.

- Use a Spreadsheet: Create a spreadsheet with columns for item description, size, weight (grams), weight (ounces), and packaging weight.

- Regularly Update: Update the database whenever you add new products or change packaging materials.

- Accessible Format: Ensure the database is easily accessible to your team, especially those involved in shipping and inventory management.

8.2. Training Staff on Accurate Weighing Techniques

- Provide Training: Conduct regular training sessions for staff on how to accurately weigh t-shirts and packaging materials.

- Demonstrate Proper Techniques: Show staff how to calibrate the scale, use the tare function, and record weights correctly.

- Emphasize Consistency: Stress the importance of consistent weighing techniques to ensure accurate data.

- Provide Resources: Provide staff with written instructions and reference materials on weighing procedures.

- Regular Audits: Conduct regular audits to ensure staff are following proper weighing techniques and maintaining accurate records.

8.3. Using Technology to Automate Weight Calculations

- Integrated Scales: Use scales that can be integrated with your e-commerce platform or shipping software.

- Automated Shipping Software: Invest in shipping software that automatically calculates shipping costs based on weight, dimensions, and destination.

- Barcode Scanners: Use barcode scanners to quickly identify products and retrieve their weights from your database.

- Inventory Management Systems: Implement an inventory management system that tracks product weights and automatically updates inventory levels.

- Cloud-Based Solutions: Opt for cloud-based solutions that allow you to access weight data from anywhere and share it with your team.

8.4. Negotiating with Suppliers for Lighter Materials

- Communicate Your Needs: Let your suppliers know that weight is a critical factor for your business and that you are looking for lighter materials and packaging options.

- Request Samples: Request samples of different fabrics and packaging materials to evaluate their weight and performance.

- Compare Options: Compare the weight and cost of different materials to find the best balance for your needs.

- Negotiate Prices: Negotiate prices with suppliers based on the weight and quality of the materials.

- Build Relationships: Build strong relationships with your suppliers to ensure they understand your needs and are willing to work with you to find solutions.

Navigating the complexities of t-shirt weights doesn’t have to be a solitary journey. At HOW.EDU.VN, our team of experienced PhDs is ready to provide personalized guidance and support, ensuring you make informed decisions every step of the way.

Don’t let the intricacies of fabric types, sizes, or shipping logistics overwhelm you. Whether you’re seeking advice on optimizing your designs, streamlining your inventory management, or minimizing shipping costs, our experts are here to help. Contact us today to schedule a consultation and discover how our tailored solutions can transform your business.

Address: 456 Expertise Plaza, Consult City, CA 90210, United States

WhatsApp: +1 (310) 555-1212

Website: how.edu.vn

9. FAQs About T-Shirt Weight

9.1. How Much Does an Average T-Shirt Weigh?

An average adult t-shirt typically weighs between 130 to 190 grams (4.6 to 6.7 ounces), depending on the fabric, size, and style.

9.2. What Is the Lightest Material for T-Shirts?

Lightweight materials like polyester and tri-blends (cotton-polyester-rayon) are among the lightest options for t-shirts.

9.3. Do Different Colors of T-Shirts Affect Weight?

Slightly, as heather finishes are lighter than solid colors. Solid colors have more dye.

9.4. How Accurate Do I Need to Be When Weighing T-Shirts for Shipping?

Aim for accuracy within a gram or 0.1 ounces to avoid discrepancies in shipping costs.

9.5. How Can I Reduce the Weight of My T-Shirt Shipments?

Optimize packaging by using lightweight materials, minimizing size, and consolidating shipments.

9.6. Is It Worth Investing in a High-Quality Scale for Weighing T-Shirts?

Yes, a high-quality scale ensures accurate measurements, saving you money on shipping costs in the long run.

9.7. How Does Humidity Affect the Weight of T-Shirts?

Humidity can increase the weight of t-shirts. Weigh items in a dry environment for more consistent results.

9.8. What Is Dimensional Weight and How Does It Affect Shipping Costs?

Dimensional weight is a calculation used by carriers to factor in the size of a package. If the dimensional weight exceeds the actual weight, the carrier will charge based on the dimensional weight.

9.9. Can I Negotiate Shipping Rates with Carriers?

Yes, businesses with high shipping volumes can often negotiate discounted rates with carriers.

9.10. What Are the Benefits of Using a Customs Broker for International Shipments?

A customs broker can help you navigate complex customs regulations, ensure compliance, and expedite the clearance process.