The question of how much a Formula 1 car costs is more complex than it appears. A Formula 1 car represents the pinnacle of motorsport engineering, a symphony of cutting-edge technology and relentless innovation. At HOW.EDU.VN, we delve into the intricate details that contribute to the staggering price tag of these racing machines. If you are seeking expert advice on motorsport investments, or simply curious about the financial aspects of F1, our team of PhDs is available to provide comprehensive guidance. Learn about the detailed cost analysis and F1 car pricing.

1. The Astonishing Price Tag: Deconstructing the Cost of an F1 Car

Understanding the cost of a Formula 1 car requires examining its numerous components and systems. From the engine to the tires, each element contributes significantly to the overall expense. The total cost of an F1 car can easily exceed $20 million, making it a substantial investment for any team.

The development, manufacturing, and maintenance costs are all factored into this figure. This section will break down the primary cost drivers, offering a clear perspective on why these machines command such high prices. Discover the financial intricacies behind F1 car development and racing.

2. The Core Components: A Detailed Look at Individual Costs

2.1. The Engine (Power Unit)

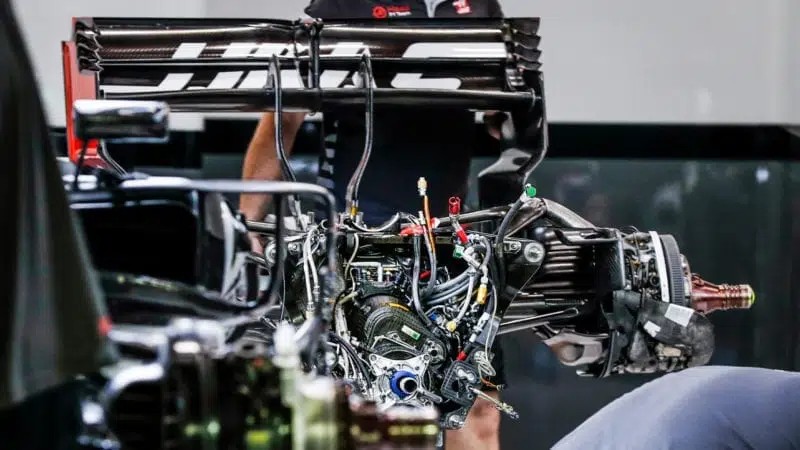

The engine, or Power Unit (PU), is one of the most expensive components of an F1 car. Since 2014, F1 has utilized 1600cc V6 turbocharged engines, and their development has been relentless. The Power Unit comprises six main components: the Internal Combustion Engine (ICE), Turbocharger (TC), Motor Generator Unit-Kinetic (MGU-K), Motor Generator Unit-Heat (MGU-H), Energy Store (ES), and Control Electronics (CE).

According to Pat Symonds, F1 teams often pay around €15 million ($18.32 million) for a single engine, considering additional components and services. This high cost reflects the complexity and precision engineering required to produce these high-performance engines. Consult experts at HOW.EDU.VN to understand the economics of F1 engine technology and performance optimization.

2.2. Gearbox

The gearbox in an F1 car is another costly component, with prices reaching up to $354,000 (£250,000). These gearboxes are semi-automatic with eight forward gears and one reverse gear. The automated sequential paddle-shift system allows for seamless shifting in approximately 0.05 seconds.

Some teams manufacture their own gearboxes, while others purchase them from suppliers. The precision and speed required for gear changes in F1 necessitate a significant investment in gearbox technology. For advice on motorsport technology investments, contact our PhD experts at HOW.EDU.VN.

2.3. Chassis

The chassis is the central structure of the F1 car, providing the foundation for all other components. Constructed from carbon fiber and other advanced materials, the chassis must be incredibly strong to withstand immense forces while remaining lightweight.

Developing and manufacturing an F1 chassis is an intricate process, involving extensive research, design, and testing. The cost can easily exceed $1 million, reflecting the complexity and critical role of this component. At HOW.EDU.VN, our experts can provide insights into the material science and engineering that underpin F1 chassis design.

2.4. Front Wing

The front wing is a crucial aerodynamic component, responsible for generating downforce and managing airflow around the car. Since 2016, front-wing designs have become increasingly complex, driving up costs.

According to Pat Symonds, a single front wing can cost at least £100,000 ($141,500). This high price is due to the intricate design and the advanced materials used in its construction. Learn more about aerodynamic engineering and its costs with expert consultation at HOW.EDU.VN.

2.5. Halo

Introduced to protect drivers’ heads from debris, the halo has proven crucial in saving lives. Developed at the Cranfield Impact Centre, the halo is built to withstand significant impact forces.

The halo costs approximately $17,000 (£12,000). While it may not be the most expensive component, its importance in driver safety makes it a vital investment. For more information on safety innovations in motorsport, consult our experts at HOW.EDU.VN.

2.6. Floor and Bargeboards

The floor of an F1 car contributes around 60% of its downforce, making it a crucial area for performance development. The floor designs have become increasingly complex, incorporating intricate features.

Combined with bargeboards, the floor can cost around £100,000 ($141,000). The aerodynamic complexity and the need for precision manufacturing contribute to this high cost. At HOW.EDU.VN, our PhDs offer expertise in aerodynamic optimization and cost management in F1.

2.7. Fuel Tank

F1 fuel tanks are designed to be nearly indestructible, made from polyurethane and Kevlar. The tank is ribbed to fill the space behind the driver’s seat, preventing collapse as fuel drains.

The fuel tank costs around $31,000 (£22,000). The high cost reflects the advanced materials and engineering required to ensure safety and reliability. Consult HOW.EDU.VN for expertise on motorsport safety and engineering.

2.8. Steering Wheel

An F1 steering wheel is constructed from carbon fiber and silicon grips. McLaren Applied Technologies supplies the standardized ECU, limiting the wheel to 20 buttons, nine rotary switches, and six paddles. Each button and switch is customizable.

Despite its size, the technology and customization make the steering wheel extremely valuable, costing around $50,000 (£35,000). At HOW.EDU.VN, our experts can provide insights into the technology and ergonomics of F1 steering systems.

2.9. Hydraulics

The hydraulics system is essential for an F1 car, controlling nine subsystems including power steering, clutch, gearshifts, DRS, and brake-by-wire.

The complexity and difficulty of implementing this system drive up the cost to around $170,000 (£123,000). For specialized advice on automotive engineering and hydraulics, contact HOW.EDU.VN.

2.10. Brake Discs and Pads

Depending on the cooling holes, an F1 brake disc can cost between $2,000 (£1,420) and $3,000 (£2,120), while pads cost $780 (£550) each. Calipers are around $5,600 (£4,000) each, and master cylinders are $5,400 (£3,800) each.

The entire F1 brake system can cost as much as $78,000 (£55,000). The need for exceptional stopping power necessitates significant investment. Consult experts at HOW.EDU.VN for insights into high-performance braking systems.

2.11. Tyres

F1 tyres are bespoke and designed for optimum performance for a limited number of laps. Pirelli provides slick, wet, and intermediate tyres, each with different compounds.

According to Pirelli Head of F1, Mario Isola, each tyre costs €600 (£520), making a set around $3,000 (£2,080). The specialized design and limited lifespan contribute to their high cost. At HOW.EDU.VN, our team can provide insights into tyre technology and performance optimization.

2.12. Additional Costs

Many ancillary components are required to run a Formula 1 car, quickly adding up in cost. A chassis loom costs £25,000 ($35,375), a wheel bearing costs £1,100 ($1,556), and driveshafts cost about £7,000 ($9,905).

These additional costs can total around $51,000 (£36,000). The cumulative effect of these small components significantly impacts the overall cost. For expert advice on motorsport cost management, contact HOW.EDU.VN.

3. The Human Factor: Salaries and Personnel Costs

Beyond the physical components, the human element significantly contributes to the cost of running an F1 team. Salaries for drivers, engineers, mechanics, and other personnel can amount to a substantial portion of a team’s budget.

Top drivers can command multi-million-dollar salaries, and experienced engineers and team managers are also highly compensated. The need for specialized expertise and skilled labor drives up these personnel costs. At HOW.EDU.VN, we offer guidance on talent management and personnel optimization in high-performance environments.

4. Research and Development: The Engine of Innovation

Research and development (R&D) is the lifeblood of Formula 1, driving innovation and performance improvements. Teams invest heavily in R&D to develop new technologies, refine existing designs, and gain a competitive edge.

This investment includes wind tunnel testing, computational fluid dynamics (CFD) simulations, and on-track testing. The costs associated with R&D can be substantial, but they are essential for staying competitive in F1. Consult our PhD experts at HOW.EDU.VN for insights into R&D strategies and technology development in motorsport.

5. Operational Expenses: Keeping the Team on Track

Operational expenses encompass a wide range of costs associated with running an F1 team, including logistics, travel, accommodation, and marketing. Transporting equipment and personnel to races around the world requires significant logistical planning and expense.

Marketing and sponsorship activities are also essential for generating revenue and maintaining a team’s visibility. These operational expenses can add up quickly, contributing to the overall cost of competing in F1. At HOW.EDU.VN, we offer guidance on operational efficiency and cost optimization for motorsport teams.

6. The Impact of Regulations: How Rules Influence Costs

Formula 1 regulations play a significant role in shaping the costs of competing. The FIA (Fédération Internationale de l’Automobile) sets rules regarding car design, engine specifications, and testing, which can impact the development and operational costs for teams.

Rule changes often require teams to invest in new technologies and designs, driving up expenses. However, regulations can also help to level the playing field and promote competition. Consult our experts at HOW.EDU.VN to understand how regulatory changes impact motorsport costs and strategies.

7. Cost-Saving Measures: Budget Caps and Standardization

In recent years, Formula 1 has implemented cost-saving measures to promote financial sustainability and reduce the disparity between teams. Budget caps limit the amount of money teams can spend on car development and operations, encouraging efficiency and innovation.

Standardization of certain components, such as the ECU, also helps to reduce costs by limiting the need for individual development. These measures aim to create a more competitive and financially viable environment for all teams. At HOW.EDU.VN, we provide insights into cost-saving strategies and financial management in motorsport.

8. The Value Proposition: What Makes an F1 Car Worth the Cost?

Despite the high costs, Formula 1 cars represent a significant value proposition for teams and manufacturers. F1 provides a platform for showcasing cutting-edge technology, promoting brand awareness, and attracting sponsorship revenue.

The performance and innovation demonstrated in F1 often translate to advancements in road car technology, benefiting consumers and driving industry progress. At HOW.EDU.VN, we can help you understand the return on investment (ROI) and strategic value of participating in Formula 1.

9. The Future of F1 Costs: Trends and Predictions

Looking ahead, the costs of Formula 1 are likely to continue evolving. New technologies, such as electric powertrains and sustainable materials, may drive up development costs in the short term but could lead to long-term savings.

Increased focus on sustainability and environmental responsibility may also impact costs, as teams invest in eco-friendly technologies and practices. Consult our experts at HOW.EDU.VN for insights into future trends and cost implications in the world of Formula 1.

10. Expert Consultation: How HOW.EDU.VN Can Help

Navigating the complex world of Formula 1 costs requires specialized expertise and insights. At HOW.EDU.VN, we offer expert consultation services to help teams, manufacturers, and investors understand the financial aspects of F1.

Our team of PhDs and industry professionals can provide guidance on cost management, technology investment, and strategic planning. Contact us today to learn how we can help you succeed in the competitive world of Formula 1. Our experts are available to provide comprehensive guidance. Whether you’re seeking motorsport investment advice or are simply curious about the financial aspects of F1, our team of PhDs is ready to assist. Reach out to us for a detailed cost analysis and insights into F1 car pricing.

In conclusion, the cost of an F1 car is a complex equation, reflecting the pinnacle of engineering, technology, and human expertise. By understanding the individual components, operational expenses, and strategic investments, teams can optimize their performance and achieve success on the track.

Are you facing challenges in managing costs or seeking expert advice on motorsport investments? Do you need assistance with strategic planning or technology development? At HOW.EDU.VN, we connect you with leading PhDs and industry experts who can provide tailored solutions to your specific needs.

Contact us today for a consultation:

- Address: 456 Expertise Plaza, Consult City, CA 90210, United States

- WhatsApp: +1 (310) 555-1212

- Website: HOW.EDU.VN

Let HOW.EDU.VN be your partner in navigating the intricate world of Formula 1, offering unparalleled expertise and support to help you achieve your goals.

FAQ: Frequently Asked Questions About F1 Car Costs

1. What is the average total cost of a Formula 1 car?

The average total cost of a Formula 1 car is approximately $20 million, including all components, development, and operational expenses.

2. Which component is the most expensive in an F1 car?

The engine, or Power Unit (PU), is the most expensive component, costing around $18.32 million.

3. How much does a single set of F1 tires cost?

A set of F1 tires costs approximately $3,000.

4. Why are F1 car components so expensive?

F1 car components are expensive due to the advanced materials, precision engineering, and extensive research and development required for optimal performance.

5. How do regulations impact the cost of F1 cars?

Regulations set by the FIA can significantly impact costs, as teams must invest in new technologies and designs to comply with rule changes.

6. What cost-saving measures have been implemented in F1?

Cost-saving measures include budget caps and standardization of certain components to reduce expenses.

7. How much does it cost to develop an F1 chassis?

Developing an F1 chassis can cost over $1 million due to the complexity and advanced materials involved.

8. What is the role of hydraulics in an F1 car, and how much does it cost?

Hydraulics control multiple subsystems in an F1 car, and the system costs around $170,000 due to its complexity.

9. How can HOW.EDU.VN help with understanding F1 car costs?

how.edu.vn provides expert consultation services with PhDs and industry professionals to help understand and manage the financial aspects of F1.

10. What are the primary operational expenses for an F1 team?

Primary operational expenses include logistics, travel, accommodation, marketing, and personnel salaries.