How Much Is A Truckload Of Concrete? Securing the right amount of concrete at the optimal price is crucial for any construction or home improvement project. At HOW.EDU.VN, we connect you with leading experts who can provide personalized advice and ensure you get the best value for your concrete needs. This comprehensive guide will cover pricing, delivery methods, and essential factors to consider, ensuring your project starts on a solid foundation.

1. Understanding the Base Cost of Concrete

The average cost of concrete typically ranges from $119 to $147 per cubic yard, which generally includes delivery up to 20 miles. However, this base price can fluctuate depending on various factors, including the concrete mix (measured in PSI), the quantity ordered, and geographical location. For specialized concrete, such as colored, stamped, or stained options, the cost can range from $8 to $18 per square foot for installation.

1.1. Factors Influencing Concrete Costs

Several elements can impact the cost of concrete:

- Concrete Mix (PSI): Higher PSI (pounds per square inch) mixes, indicating greater strength, generally cost more per cubic yard.

- Volume: Ordering less than a full truckload (typically 10 cubic yards) usually incurs additional “short load” fees.

- Delivery Distance: Exceeding the standard delivery radius (usually 20 miles) can result in extra charges per mile.

- Special Finishes: Decorative options like coloring, stamping, or staining increase the overall cost.

- Time of Delivery: Weekend or after-hours deliveries may incur supplementary charges.

1.2. Regional Price Variations

Concrete prices can vary significantly based on location due to factors such as:

- Local Material Costs: The cost of raw materials (cement, aggregates, etc.) can differ by region.

- Transportation Costs: Distance from the concrete mixing plant to your job site affects delivery expenses.

- Local Demand: Areas with high construction activity may experience increased concrete prices.

- Environmental Regulations: Stricter regulations can raise production costs.

2. Delving into Concrete Cost Per Yard

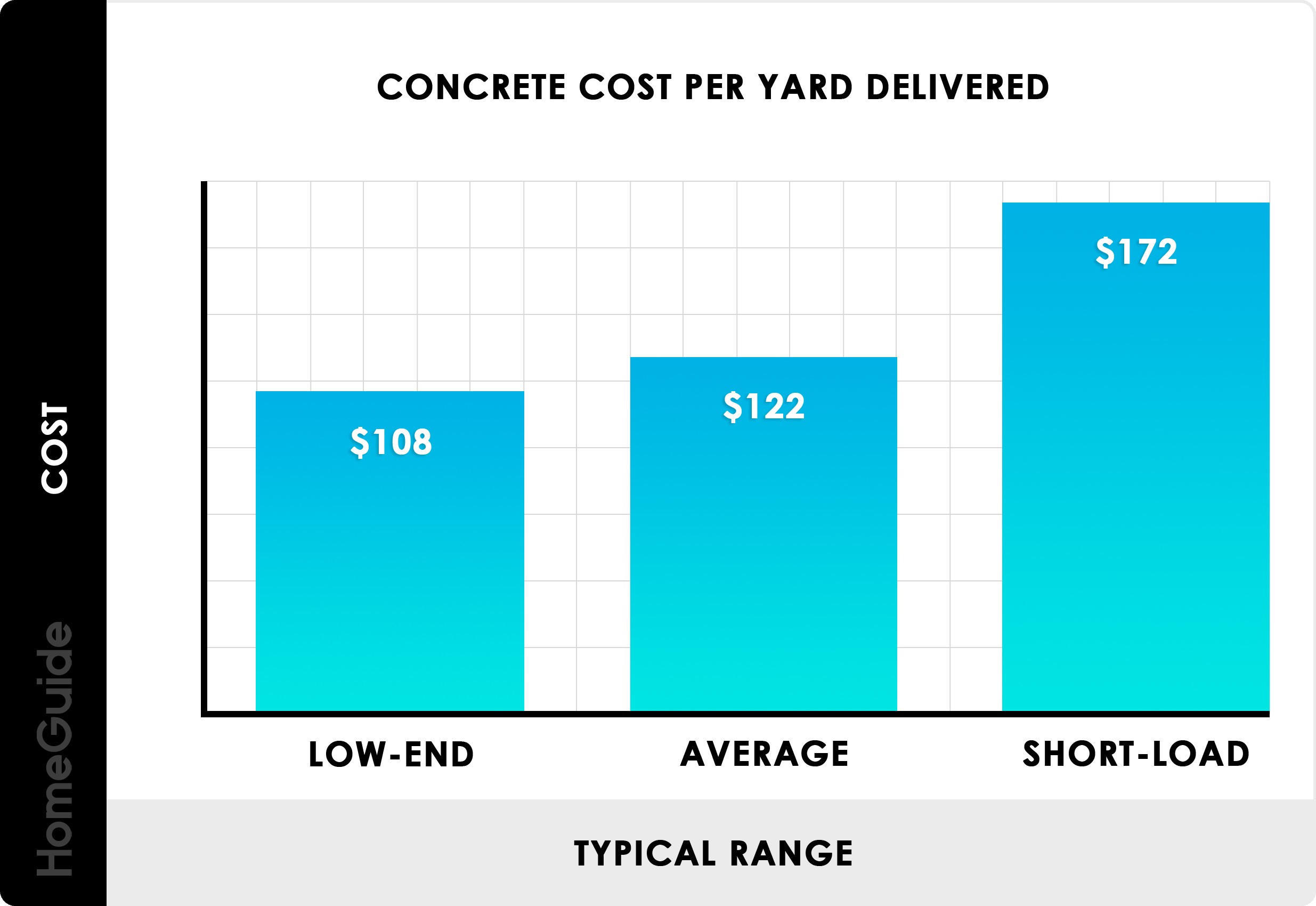

The concrete cost per yard provides a fundamental understanding of pricing. According to the NRMCA (National Ready Mixed Concrete Association), the average cost of concrete is around $108 per cubic yard. However, for most homeowners, the delivered cost averages between $119 and $147 per cubic yard, depending on the cement’s PSI.

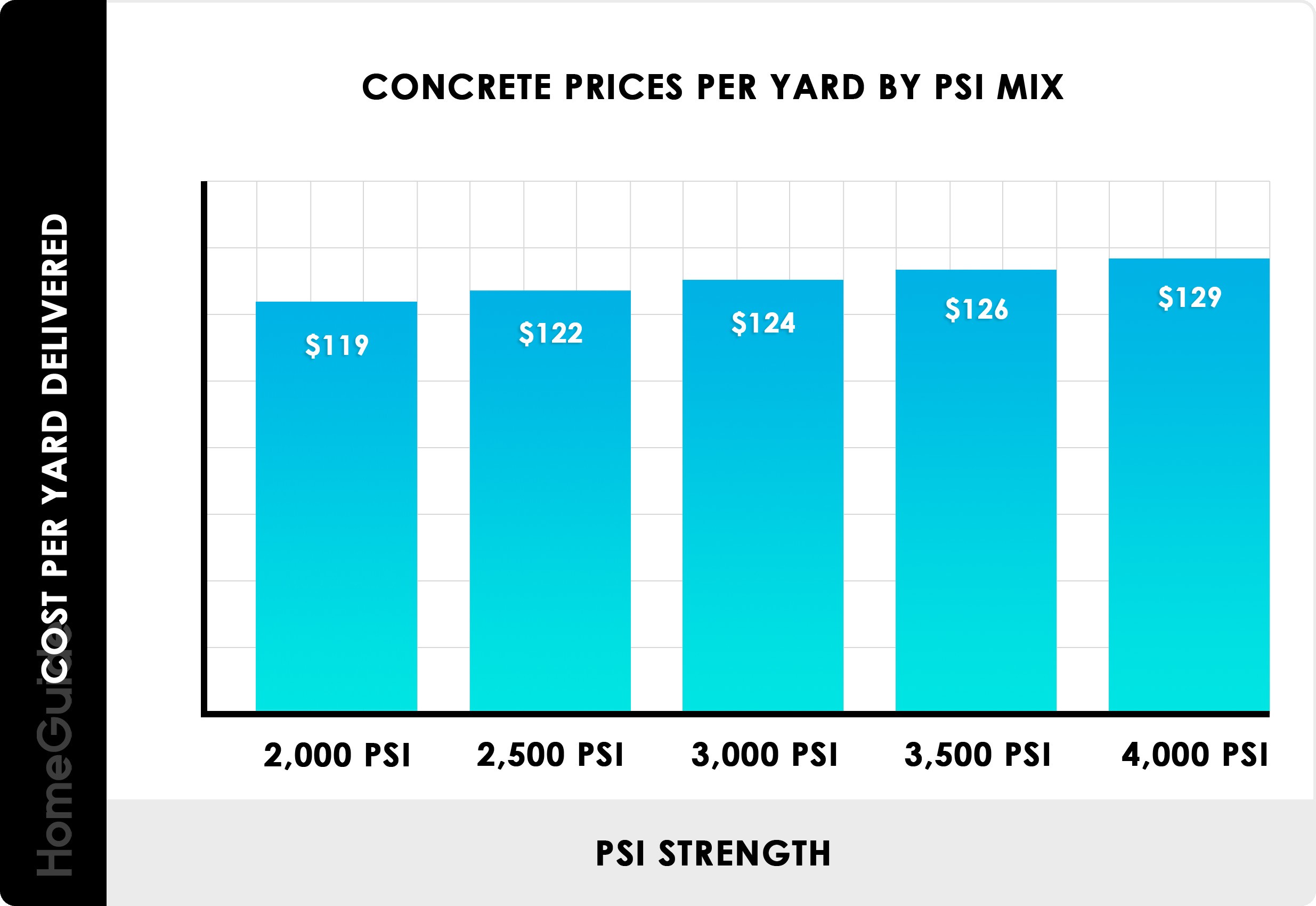

2.1. The Impact of PSI on Price

PSI (pounds per square inch) measures the compressive strength of concrete. Higher PSI mixes are used for more demanding applications and typically cost more. Here’s a general guideline:

- 2,500 PSI: Suitable for walkways and sidewalks.

- 3,000 PSI: Ideal for foundations and floor slabs.

- 4,000 PSI: Used for commercial pavement and high-traffic areas.

- 5,000 PSI: Necessary for special construction areas requiring high impact resistance.

2.2. Cost Add-ons

Several factors can add to the base cost per cubic yard:

- Short Load Fee: Orders less than 10 cubic yards may incur an extra $53 per cubic yard.

- Saturday Delivery: Expect to pay an additional $8 per cubic yard for weekend delivery.

- Coloring: Adding color can increase the price by $31 to $170 per cubic yard.

- Stamped Concrete: Stamping can add $45 to $108 per cubic yard.

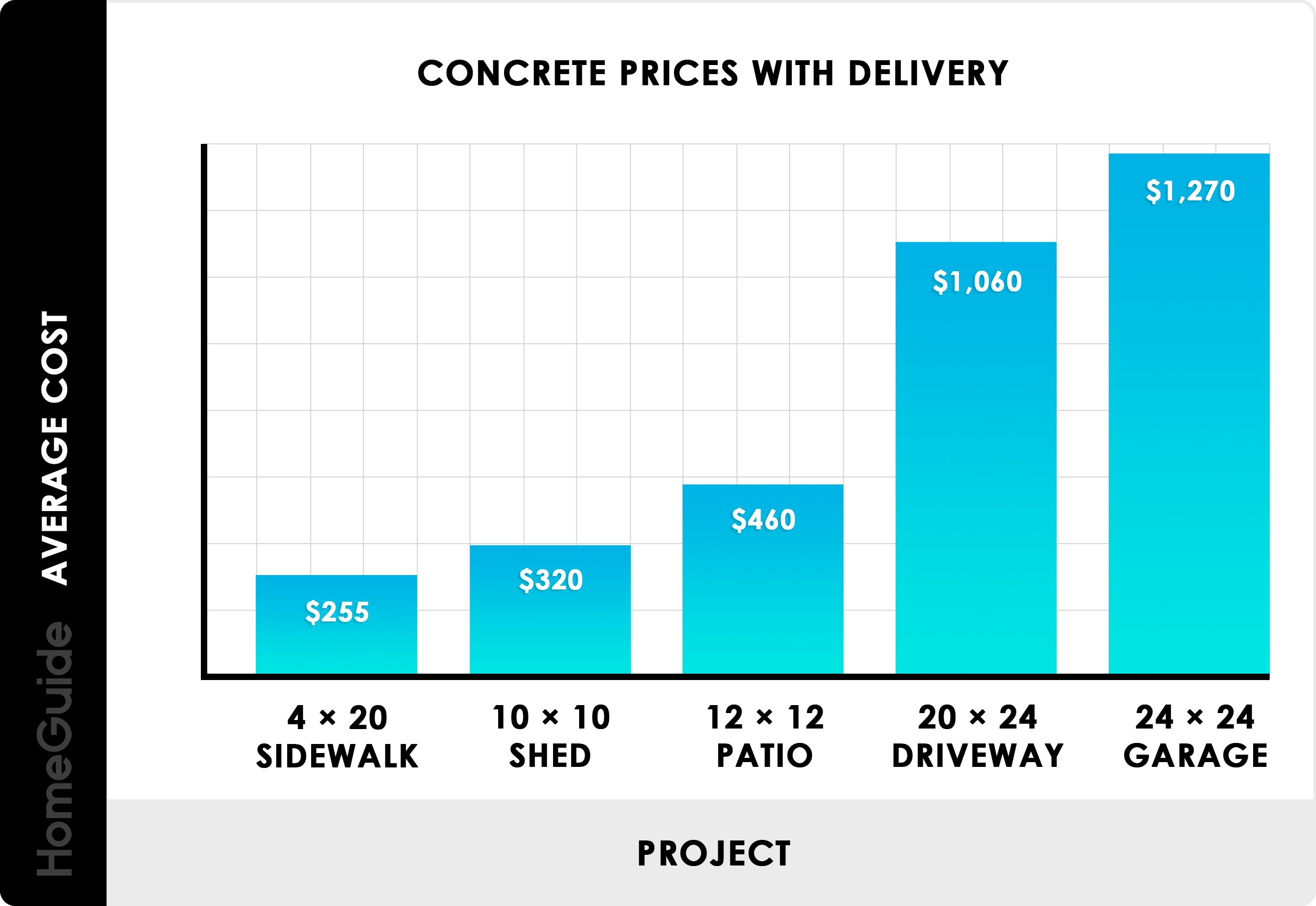

3. Calculating Full Truckload Costs

A full truckload of concrete usually contains about 10 cubic yards. The cost for a full truckload ranges between $1,169 and $1,444, depending on the PSI mix.

3.1. Short Load vs. Full Load

- Full Load: A full truckload is cost-effective for larger projects as it avoids short load fees.

- Short Load: If you need less than 10 cubic yards, be prepared to pay extra per cubic yard.

3.2. Volume Discounts

For extremely large projects, some suppliers may offer volume discounts. Negotiating with your supplier could lead to significant savings if you require a large quantity of concrete.

4. Exploring Bulk Concrete and Price Per Ton

For very large commercial projects, concrete might be measured and delivered in tons. One cubic yard of concrete is approximately 2.03 short tons, costing an average of $50 to $75 per ton.

4.1. Commercial vs. Residential Pricing

Commercial projects often have different pricing structures compared to residential jobs. Factors like volume, payment terms, and ongoing relationships can influence the price per ton.

4.2. Benefits of Buying in Bulk

Purchasing in bulk can be advantageous for large-scale construction due to:

- Potential Discounts: Suppliers may offer reduced rates for large orders.

- Consistent Supply: Ensures a steady flow of materials, reducing downtime.

- Simplified Logistics: Managing fewer, larger deliveries can streamline operations.

5. Concrete Delivery Options and Costs

Choosing the right type of concrete delivery is vital for managing costs and ensuring the project’s success. The two most common types of delivery are short load and ready-mix.

5.1. Short Load Concrete Prices

Short load concrete is generally used for small to medium-sized residential projects where the concrete is mixed on-site. The dry concrete typically fits in one truckload. Each cubic yard of concrete delivered in this manner costs between $119 and $147, with an additional $53 per cubic yard for it being a short load, totaling approximately $172 per yard.

| Cubic Yards | Mixing On-site Fees |

|---|---|

| 6 – 6.75 | $60 |

| 5 – 5.75 | $70 |

| 4 – 4.75 | $80 |

| 3 – 3.75 | $90 |

| 2 – 2.75 | $100 |

| 1 – 1.75 | $110 |

5.2. Ready-Mix Concrete Prices

Ready-mix concrete is pre-mixed at a plant and delivered ready to pour, typically used for larger projects like driveways and garage slabs. The price ranges from $119 to $147 per cubic yard, including delivery up to 20 miles.

| Item | Average Cost |

|---|---|

| Base Cost | $119 – $147 per cubic yard |

| Add For Delivery Over 20 Miles | + $9.50 per mile |

| Add For Less Than 10 CY Per Load | + $53 per cubic yard |

| Add For Saturday Delivery | + $8 per cubic yard |

| Add For Standby Charge | + $3 per minute |

| Base Cost For Special Finishes | + $96 per truckload |

| Add For Coloring | + $31 – $170 per cubic yard |

| Add For Stamped Concrete | + $45 – $108 per cubic yard |

5.3. Hauling Your Own Concrete

Another option is hauling your own concrete, typically up to 1 cubic yard at a time. Renting a small concrete mixer attached to a trailer will add $10 per cubic yard to your concrete price, or a flat fee of $120 per day.

6. Essential Prep Work Before Concrete Pouring

Proper preparation before pouring concrete is crucial for a successful and durable project. This includes grading, subbase preparation, and form construction.

6.1. Grading Costs

Grading ensures water drains away from your home and doesn’t pool under the concrete, which can cause cracking. Grading costs around $60 per hour for a tractor and operator. For larger projects, land clearing can range from $1,150 to $3,700.

6.2. Subbase Preparation

A sub-base of gravel and sand needs to be laid and compacted at $10 to $20 per cubic yard to reduce the chance of concrete shifting and cracking.

6.3. Concrete Form Costs

Plywood forming with stakes, nails, and form oil is required for pouring concrete. Concrete edge forms for driveways and sidewalks cost $2 to $3 per linear foot to install, while forms for foundation walls, building walls, and retaining walls cost $2.50 to $6.00 per square foot of contact area.

| Edge Form Type | Average Cost |

|---|---|

| Driveways and Sidewalks | $2 – $3 per linear foot |

| Foundation Walls, Building Walls & Retaining Walls | $2.50 – $6.00 per sq ft |

6.4. Reinforcement and Finishing

Adding concrete reinforcement wire mesh costs $0.15 – $0.30 per square foot, while rebar ranges from $0.30 to $0.50 per linear foot, which helps prevent large cracks and makes your concrete project structurally sound.

Colored concrete can add $31 per cubic yard for common colors like tan or brown, while specialty colors like blue can add up to $170 per cubic yard.

Stamped concrete costs $8 – $18 per square foot.

7. Pre-Mix Concrete Prices

Pre-mixed concrete costs $4.49 to $5.57 per 50-pound bag and is available at most home improvement stores. These mixes are suitable for small residential projects.

| Cement Type | Prices Per Sack |

|---|---|

| Light-weight Concrete (50 lb.) | $4.49 |

| Concrete Mix, Fast Setting (50 lb.) | $4.57 |

| Mortar Mix (60 lb.) | $5.57 |

Each bag size yields a different amount:

- 50-pound bag yields .014 cubic yards

- 60-pound bag yields .017 cubic yards

- 90-pound bag yields .025 cubic yards

8. Concrete Equipment Rental Costs

Depending on your project’s scope, you may need to rent equipment. For example, renting a cement mixer on a trailer for small jobs costs $120 per day or $390 for a week.

| Equipment | Day | Week | Month |

|---|---|---|---|

| Concrete Buggies | $100 | $300 | $700 |

| Concrete Vibrator | $75 | $200 | $500 |

| Screed Concrete Vibrators | $85 | $280 | $600 |

| Troweling Machine | $70 | $225 | $600 |

| Power Trowel | $70 | $220 | $620 |

9. DIY Concrete Installation Tips

- Be Precise: Accurately measure and order the correct amount of concrete, adding 5% to 10% for waste.

- Have Proper Tools: Ensure you have essential tools like a square mouth shovel, screed board, and steel trowel.

- Build a Proper Form: Use 2x4s for the sides and stakes for the corners.

- Reinforce the Concrete: Use wire mesh or rebar for added strength.

- Cure the Concrete: Use a cure-and-seal compound to minimize cracking.

10. Concrete PSI for Various Applications

PSI measures the strength of concrete. The recommended PSI depends on the application.

| PSI | Uses |

|---|---|

| 2,500 | Walkways, driveways, floors, sidewalks |

| 3,000 | General construction, foundations, floor slabs |

| 4,000 | Pavement, commercial, high-traffic areas |

| 5,000 | Special construction, high impact areas |

11. FAQs

11.1. Where Do You Buy Concrete?

For small projects, purchase pre-mixed bags from home improvement stores. For larger projects, call a ready-mix concrete delivery company.

11.2. What Is The Cheapest Way To Buy Concrete?

Mix your own by purchasing pre-mixed bags and renting a concrete mixer. Buying a full truckload is the next best option.

11.3. How Do You Order Concrete?

Contact the dispatch department of a concrete contractor, provide your project dimensions, and ask about additives like reinforced fiber.

11.4. How Many Cubic Yards of Concrete Are In A Truck?

Approximately 10 cubic yards, costing $1,169 to $1,444 delivered.

11.5. What Is The Minimum Amount of Concrete for Delivery?

The minimum is a truckload of about 10 cubic yards at $119 to $147 per cubic yard, with extra fees for smaller amounts.

11.6. How Long Does It Take to Pour Concrete?

A crew can set forms and pour 40 to 50 cubic yards in an 8-hour day. Pumping a truckload takes 60 to 90 minutes.

11.7. Can You Pour Concrete in a Hole with Water?

Yes, if the water is calm.

11.8. Can You Pour Concrete Over Grass?

Yes, but rototill the area first to break up the vegetation.

11.9. What Is the Difference Between Concrete and Cement?

Cement is an ingredient in concrete.

11.10. What Is a Lean Mix of Concrete?

A lower ratio of cement to liquid, ideal as a base layer.

11.11. How Far Can Concrete Be Pumped?

Residential concrete pumping uses booms that pump up to 100 feet.

11.12. How Much Does a Concrete Pump Truck Cost Per Hour?

$140 to $190 per hour, with a 4- to 5-hour minimum.

12. Ensuring a Smooth Project

To ensure the success of your concrete project, consider the following:

12.1. Detailed Planning

Start with a comprehensive plan that outlines the scope of the project, budget, timeline, and any specific design requirements. Proper planning helps avoid costly surprises and keeps the project on track.

12.2. Accurate Measurements

Precise measurements are critical for ordering the correct amount of concrete. Overestimating is better than underestimating to avoid a “cold seam,” but accuracy can minimize waste.

12.3. Site Accessibility

Ensure that the delivery site is easily accessible for concrete trucks. Clear any obstructions and provide a clear path to the pouring location to avoid delays and additional charges.

12.4. Weather Considerations

Check the weather forecast before scheduling your concrete delivery. Extreme temperatures (both hot and cold) can affect the curing process and the final strength of the concrete.

12.5. Proper Curing Techniques

Curing is the process of maintaining moisture in the concrete to ensure proper hydration and strength development. Use methods like covering the concrete with plastic sheeting, applying curing compounds, or regularly sprinkling the surface with water.

12.6. Quality Control Checks

Regularly inspect the concrete as it is being poured and finished to ensure it meets your quality standards. Check for proper mixing, consistent color, and correct placement of reinforcement.

12.7. Safety Measures

Prioritize safety throughout the project. Wear appropriate protective gear, such as gloves, safety glasses, and sturdy boots. Follow all safety guidelines for operating equipment and handling materials.

12.8. Waste Management

Plan for proper disposal of any leftover concrete and materials. Contact local recycling centers or waste management services to determine the best disposal methods.

13. Why Choose HOW.EDU.VN for Your Concrete Project?

Planning a concrete project involves understanding various factors, from material costs to specialized finishes. However, navigating these complexities alone can be overwhelming. At HOW.EDU.VN, we provide direct access to a team of distinguished experts who can offer personalized guidance tailored to your specific needs. Here’s how we can help:

13.1. Access to Top-Tier Expertise

Our team includes over 100 Ph.D.-level consultants and industry specialists, ready to provide expert advice on every aspect of your concrete project. Whether you’re determining the precise PSI mix for your driveway or optimizing costs for a commercial build, our experts offer unparalleled insights.

13.2. Personalized Consultations

We recognize that every project is unique. That’s why we offer one-on-one consultations designed to address your specific challenges and goals. Our experts work closely with you to understand your needs and provide solutions that align with your vision and budget.

13.3. Cost-Effective Solutions

Concerned about costs? Our experts excel at identifying strategies to maximize value without compromising quality. From negotiating with suppliers to selecting the most efficient delivery methods, we help you make informed decisions that keep your project financially sound.

13.4. Risk Mitigation

Our experts help you proactively identify and mitigate potential risks. Whether it’s anticipating weather-related challenges or ensuring compliance with local regulations, we help you navigate potential pitfalls with confidence.

13.5. Project Oversight

For larger or more complex projects, our experts can provide ongoing oversight, ensuring that every phase is executed flawlessly. From initial planning to final inspection, we’re there to support you every step of the way.

14. Take the Next Step with HOW.EDU.VN

Don’t let the complexities of your concrete project overwhelm you. Contact HOW.EDU.VN today and connect with the expertise you need to ensure success. Our team of experienced consultants is ready to provide the personalized guidance and support you deserve.

Whether you’re a homeowner embarking on a DIY project or a construction professional managing a large-scale build, HOW.EDU.VN is your trusted partner for all things concrete.

14.1. How to Get Started

- Visit our website: HOW.EDU.VN.

- Explore our consultant profiles: Learn about our experts’ backgrounds and areas of specialization.

- Request a consultation: Fill out our online form or call us directly to schedule a personalized consultation.

We look forward to helping you achieve your concrete project goals with confidence and ease. Contact us today to discover the difference expert guidance can make.

Address: 456 Expertise Plaza, Consult City, CA 90210, United States.

WhatsApp: +1 (310) 555-1212.

Website: how.edu.vn