How Much Does A Plane Weigh? The weight of a plane varies significantly, ranging from a few thousand pounds for light aircraft to over a million pounds for the largest commercial airliners. At HOW.EDU.VN, we provide expert insights to help you understand the different factors influencing aircraft weight and its importance in aviation. Discover the details of aircraft weight, weight distribution, and its impact on flight performance, and connect with leading experts for personalized guidance.

1. Understanding Aircraft Weight: Key Factors

Aircraft weight is a critical parameter in aviation, influencing everything from fuel consumption to takeoff and landing performance. Understanding the factors that determine how much a plane weighs is essential for pilots, engineers, and aviation enthusiasts alike.

1.1. Basic Empty Weight (BEW)

The Basic Empty Weight (BEW) includes the weight of the aircraft itself, along with all standard operating equipment, unusable fuel, and fluids. It does not include passengers, usable fuel, or cargo. This baseline weight is crucial for calculating the aircraft’s overall weight and balance.

1.2. Operating Empty Weight (OEW)

The Operating Empty Weight (OEW) builds on the BEW by adding the weight of the crew, crew baggage, food, and other essential items required for a specific flight. This weight provides a more accurate picture of the aircraft’s weight before passengers and cargo are loaded.

1.3. Payload

Payload refers to the weight of passengers, cargo, and baggage that an aircraft carries. The amount of payload an aircraft can carry is determined by its maximum takeoff weight (MTOW) and other weight limitations.

1.4. Fuel Weight

Fuel weight is a significant factor affecting an aircraft’s overall weight, especially for long-haul flights. The amount of fuel required depends on the distance to be flown, weather conditions, and other operational factors.

1.5. Maximum Takeoff Weight (MTOW)

The Maximum Takeoff Weight (MTOW) is the maximum weight at which the aircraft is certified to take off. This weight includes the aircraft’s empty weight, payload, and fuel. Exceeding the MTOW can compromise safety and performance.

1.6. Maximum Landing Weight (MLW)

The Maximum Landing Weight (MLW) is the maximum weight at which an aircraft is certified to land. It is typically less than the MTOW due to fuel burn during the flight. Landing above the MLW can put excessive stress on the aircraft’s landing gear.

1.7. Zero Fuel Weight (ZFW)

The Zero Fuel Weight (ZFW) is the total weight of the aircraft and its contents, excluding usable fuel. This weight is important for calculating the aircraft’s weight and balance, as it represents the weight that must be supported by the wings.

2. Weight Categories: From Light Aircraft to Heavy Jets

Aircraft are categorized based on their maximum takeoff weight (MTOW), which significantly influences their operational capabilities and intended use. Let’s explore the different weight categories and some examples of aircraft in each category.

2.1. Light Aircraft

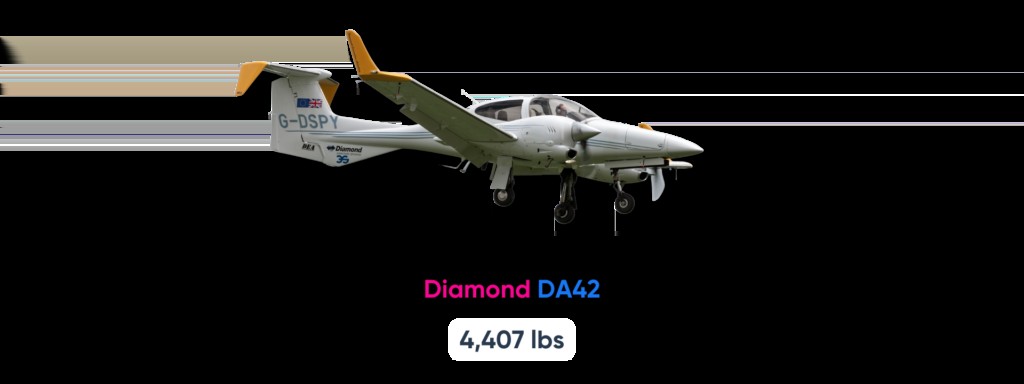

Light aircraft typically have a Maximum Takeoff Weight (MTOW) of less than 12,500 pounds. These aircraft are commonly used for personal flying, flight training, and short-distance travel.

2.1.1. Cessna 172 Skyhawk

The Cessna 172 Skyhawk is one of the most popular light aircraft in the world, with an MTOW of around 2,450 pounds. It is widely used for flight training and personal transportation.

2.1.2. Piper PA-28 Cherokee

The Piper PA-28 Cherokee is another common light aircraft, with an MTOW ranging from 2,400 to 2,900 pounds, depending on the specific model. It is known for its reliability and ease of handling.

2.1.3. Cirrus SR22

The Cirrus SR22 is a high-performance light aircraft with an MTOW of around 3,600 pounds. It features advanced avionics and safety features, making it a popular choice for personal and business travel.

2.2. Business Jets

Business jets are designed for corporate and private use, offering comfortable and efficient transportation for small groups of passengers. Their MTOW typically ranges from 12,500 to 100,000 pounds.

2.2.1. Embraer Phenom 300

The Embraer Phenom 300 is a light business jet with an MTOW of around 17,968 pounds. It offers a spacious cabin and impressive performance, making it a popular choice for short to medium-range flights.

2.2.2. Bombardier Challenger 350

The Bombardier Challenger 350 is a super-midsize business jet with an MTOW of approximately 44,300 pounds. It features a luxurious cabin and long-range capabilities, suitable for transcontinental travel.

2.2.3. Gulfstream G650

The Gulfstream G650 is a large-cabin business jet with an MTOW of around 99,600 pounds. It offers exceptional range, speed, and comfort, making it a favorite among high-net-worth individuals and corporations.

2.3. Regional Airliners

Regional airliners are designed for short to medium-range flights, typically serving smaller airports and connecting them to larger hubs. Their MTOW generally ranges from 50,000 to 150,000 pounds.

2.3.1. Embraer E175

The Embraer E175 is a popular regional airliner with an MTOW of approximately 93,000 pounds. It offers a comfortable cabin and efficient operation, making it a preferred choice for regional airlines.

2.3.2. Bombardier CRJ900

The Bombardier CRJ900 is another common regional airliner, with an MTOW of around 84,500 pounds. It is known for its fuel efficiency and versatility, serving a wide range of routes.

2.4. Narrow-Body Airliners

Narrow-body airliners are designed for short to medium-haul flights, typically carrying between 100 and 200 passengers. Their MTOW usually ranges from 150,000 to 250,000 pounds.

2.4.1. Boeing 737-800

The Boeing 737-800 is one of the most popular narrow-body airliners in the world, with an MTOW of approximately 174,200 pounds. It is known for its reliability, fuel efficiency, and versatility.

2.4.2. Airbus A320

The Airbus A320 is another widely used narrow-body airliner, with an MTOW ranging from 160,000 to 172,000 pounds, depending on the specific variant. It offers a comfortable cabin and advanced technology.

2.5. Wide-Body Airliners

Wide-body airliners are designed for long-haul flights, typically carrying between 200 and 500 passengers. Their MTOW usually ranges from 500,000 to 800,000 pounds.

2.5.1. Boeing 777-300ER

The Boeing 777-300ER is a popular wide-body airliner with an MTOW of around 775,000 pounds. It offers exceptional range, payload capacity, and fuel efficiency, making it a favorite among long-haul airlines.

2.5.2. Airbus A350-900

The Airbus A350-900 is a modern wide-body airliner with an MTOW of approximately 617,300 pounds. It features advanced aerodynamics, fuel-efficient engines, and a comfortable cabin.

2.6. Heavy Jets

Heavy jets are the largest and heaviest aircraft, designed for long-haul flights and capable of carrying significant amounts of cargo or passengers. Their MTOW exceeds 800,000 pounds.

2.6.1. Boeing 747-8

The Boeing 747-8 is one of the most iconic heavy jets, with an MTOW of around 987,000 pounds. It can carry a large number of passengers or a substantial amount of cargo over long distances.

2.6.2. Airbus A380

The Airbus A380 is the world’s largest passenger airliner, with an MTOW of approximately 1,268,000 pounds. It can carry over 800 passengers in a typical configuration, offering a luxurious and comfortable flying experience.

Understanding the weight categories of aircraft and their corresponding MTOW is essential for appreciating the diversity and capabilities of modern aviation.

3. The Role of Weight in Aircraft Performance

Weight plays a critical role in aircraft performance, influencing various aspects of flight, including takeoff, climb, cruise, and landing. Understanding how weight affects these performance parameters is essential for pilots and aircraft designers.

3.1. Takeoff Performance

The weight of an aircraft directly affects its takeoff performance. Heavier aircraft require longer takeoff distances and higher takeoff speeds. Pilots must carefully calculate takeoff performance based on the aircraft’s weight, runway length, and environmental conditions.

3.2. Climb Performance

Weight also affects an aircraft’s climb performance. Heavier aircraft have a lower rate of climb and require more power to achieve a given altitude. Pilots must consider the aircraft’s weight when planning climbs, especially in mountainous terrain or when encountering obstacles.

3.3. Cruise Performance

During cruise, weight affects an aircraft’s speed, fuel consumption, and range. Heavier aircraft typically have lower cruise speeds and higher fuel consumption rates. Pilots must optimize cruise performance by selecting the appropriate altitude and power settings for the aircraft’s weight.

3.4. Landing Performance

The weight of an aircraft also affects its landing performance. Heavier aircraft require longer landing distances and higher approach speeds. Pilots must carefully plan their approach and landing based on the aircraft’s weight, runway length, and wind conditions.

4. Weight and Balance: Ensuring Safe Flight

Weight and balance are critical aspects of flight safety. Proper weight distribution ensures that the aircraft remains stable and controllable throughout the flight envelope.

4.1. Center of Gravity (CG)

The Center of Gravity (CG) is the point at which the aircraft would balance if suspended. The CG location is critical for stability and control. If the CG is too far forward or aft, the aircraft may become difficult to control.

4.2. Weight Distribution

Proper weight distribution is essential for maintaining the CG within acceptable limits. Pilots must carefully load passengers, cargo, and fuel to ensure that the CG remains within the specified range.

4.3. Weight and Balance Calculations

Pilots use weight and balance calculations to determine the CG location and ensure that the aircraft is within weight and balance limits. These calculations take into account the weight and location of all items on board the aircraft.

4.4. Adverse Effects of Improper Weight and Balance

Improper weight and balance can have serious consequences, including:

- Reduced stability and control

- Increased takeoff and landing distances

- Reduced climb performance

- Increased fuel consumption

- Structural damage

5. Regulations and Standards for Aircraft Weight

Aircraft weight is subject to strict regulations and standards to ensure safety and operational efficiency. These regulations are set by aviation authorities such as the Federal Aviation Administration (FAA) in the United States and the European Aviation Safety Agency (EASA) in Europe.

5.1. FAA Regulations

The FAA sets regulations for aircraft weight and balance in the United States. These regulations cover various aspects of aircraft operation, including:

- Weight and balance limitations

- Weight and balance calculations

- Weight and balance documentation

- Weight and balance training

5.2. EASA Regulations

EASA sets regulations for aircraft weight and balance in Europe. These regulations are similar to those of the FAA and cover the same aspects of aircraft operation.

5.3. International Standards

International standards for aircraft weight and balance are set by the International Civil Aviation Organization (ICAO). These standards are adopted by many countries around the world to ensure consistency and safety in aviation operations.

6. Technological Advancements in Weight Reduction

Aircraft manufacturers are constantly seeking ways to reduce aircraft weight to improve performance, fuel efficiency, and payload capacity. Technological advancements in materials, design, and manufacturing processes have played a significant role in weight reduction.

6.1. Composite Materials

Composite materials, such as carbon fiber reinforced polymers (CFRP), are increasingly used in aircraft construction due to their high strength-to-weight ratio. These materials are lighter than traditional aluminum alloys, allowing for significant weight savings.

6.2. Advanced Alloys

Advanced aluminum and titanium alloys are also used in aircraft construction to reduce weight while maintaining strength and durability. These alloys offer improved properties compared to traditional materials.

6.3. Optimized Design

Aircraft designers use advanced computer-aided design (CAD) and finite element analysis (FEA) tools to optimize the structural design of aircraft components. This allows them to minimize weight while ensuring structural integrity.

6.4. Additive Manufacturing

Additive manufacturing, also known as 3D printing, is a revolutionary technology that allows for the creation of complex aircraft components with minimal material waste. This technology can be used to produce lightweight parts with optimized geometries.

7. Case Studies: Aircraft Weight Optimization

Several aircraft manufacturers have successfully implemented weight optimization strategies to improve the performance and efficiency of their aircraft. Here are a few notable case studies:

7.1. Boeing 787 Dreamliner

The Boeing 787 Dreamliner is a prime example of an aircraft designed with weight optimization in mind. The aircraft’s structure is made primarily of composite materials, resulting in significant weight savings compared to traditional aluminum designs.

7.2. Airbus A350 XWB

The Airbus A350 XWB also incorporates a significant amount of composite materials in its structure. This allows for improved fuel efficiency and reduced operating costs.

7.3. Embraer E-Jets E2

The Embraer E-Jets E2 family of regional airliners features optimized aerodynamics and lightweight materials to improve fuel efficiency and reduce emissions.

8. Consulting with Experts at HOW.EDU.VN

Navigating the complexities of aircraft weight and its impact on flight operations requires expert knowledge and experience. At HOW.EDU.VN, we connect you with leading experts in aviation engineering, flight operations, and aircraft design.

8.1. Expert Guidance

Our team of experienced professionals can provide you with expert guidance on all aspects of aircraft weight, including:

- Weight and balance calculations

- Weight optimization strategies

- Regulatory compliance

- Aircraft performance analysis

8.2. Personalized Solutions

We understand that every aircraft and operation is unique. That’s why we offer personalized solutions tailored to your specific needs and requirements.

8.3. Access to Cutting-Edge Knowledge

Our experts stay up-to-date with the latest advancements in aviation technology and regulations. We provide you with access to cutting-edge knowledge and best practices.

8.4. Connect with Leading PhDs

At HOW.EDU.VN, we connect you directly with PhDs and leading experts worldwide. Our experts offer in-depth consultations and personalized solutions, saving you time and ensuring reliable advice. We guarantee confidentiality and deliver practical, immediately applicable solutions.

9. The Future of Aircraft Weight Management

Aircraft weight management will continue to be a critical area of focus in the aviation industry. Future trends and developments include:

9.1. Increased Use of Composite Materials

Composite materials will continue to replace traditional aluminum alloys in aircraft construction. This will lead to further weight reductions and improved fuel efficiency.

9.2. Development of Lighter Engines

Engine manufacturers are developing lighter and more efficient engines. These engines will contribute to overall weight reduction and improved aircraft performance.

9.3. Advanced Aerodynamic Designs

Advanced aerodynamic designs will help reduce drag and improve lift, allowing for further weight optimization.

9.4. Smart Structures

Smart structures with integrated sensors and actuators will enable real-time monitoring and control of aircraft weight and balance. This will improve safety and operational efficiency.

10. Conclusion: Mastering Aircraft Weight for Optimal Performance

Understanding aircraft weight is crucial for safe and efficient flight operations. From light aircraft to heavy jets, weight affects every aspect of flight performance, from takeoff to landing. By mastering the principles of weight and balance, and by leveraging technological advancements in weight reduction, pilots and aircraft designers can optimize aircraft performance and ensure safe and reliable operations.

For expert guidance and personalized solutions, contact HOW.EDU.VN today. Our team of experienced professionals is ready to help you navigate the complexities of aircraft weight and achieve your aviation goals.

Ready to optimize your flight operations with expert guidance? Contact HOW.EDU.VN today and connect with our team of experienced aviation professionals. Let us help you master the principles of aircraft weight and balance, and achieve your aviation goals.

Contact Information:

- Address: 456 Expertise Plaza, Consult City, CA 90210, United States

- WhatsApp: +1 (310) 555-1212

- Website: HOW.EDU.VN

Don’t let the complexities of aircraft weight hold you back. Partner with HOW.EDU.VN and experience the difference that expert guidance can make.

FAQ: Understanding Aircraft Weight

1. What is Maximum Takeoff Weight (MTOW)?

The Maximum Takeoff Weight (MTOW) is the maximum weight at which an aircraft is certified to take off. This weight includes the aircraft’s empty weight, payload, and fuel.

2. Why is aircraft weight important?

Aircraft weight is critical because it affects takeoff and landing distances, climb rate, cruise speed, fuel consumption, and overall safety.

3. What factors influence aircraft weight?

Factors include the aircraft’s basic empty weight, operating empty weight, payload, fuel weight, and any additional cargo or equipment.

4. How do pilots calculate weight and balance?

Pilots use weight and balance manuals and loading schedules to calculate the aircraft’s center of gravity (CG) and ensure it falls within acceptable limits.

5. What are the consequences of exceeding MTOW?

Exceeding MTOW can lead to longer takeoff distances, reduced climb performance, increased stress on the airframe, and potential safety hazards.

6. How do composite materials help reduce aircraft weight?

Composite materials like carbon fiber are lighter and stronger than traditional aluminum, allowing for significant weight savings without compromising structural integrity.

7. What is Zero Fuel Weight (ZFW)?

Zero Fuel Weight (ZFW) is the total weight of the aircraft and its contents, excluding usable fuel. It’s an important value for weight and balance calculations.

8. How do aviation regulations address aircraft weight?

Aviation authorities like the FAA and EASA set strict regulations for weight and balance to ensure safe operation and prevent accidents.

9. Can advanced technology help optimize aircraft weight?

Yes, technologies like 3D printing, advanced alloys, and optimized structural designs contribute to reducing aircraft weight.

10. How can HOW.EDU.VN experts assist with aircraft weight-related concerns?

how.edu.vn connects you with aviation experts who can provide guidance on weight and balance calculations, weight optimization strategies, regulatory compliance, and aircraft performance analysis.